Feature

♦ Accurate and stable flow rate.

♦ Can be loaded with stainless steel syringes for high pressure or viscous liquid transmission.

♦ Accuracy and stability of liquid injection.

♦ Power-off memory function.

♦ Simple to complex programming operations can be performed without a computer.

Application

♦ High thrust injection

♦ Highly corrosive liquid injection

♦ High viscosity liquid injection

♦ Micro high precision injection

♦ Injection into a high-pressure containe

Technical Parameter

Syringe size: 0.5μL~140mL

Flow range: 3.000pL/min(0.5μL syringe)~214.915mL/min(140mL syringe)

Working mode: Infuse, withdraw, infuse /withdraw, withdraw/infuse, continuous mode

Channel: 1 Channel

Stroke of pump: 140mm

Pusher advance: 0.156μm/μstep

Linear speed: 0.36μm/min~190mm/min

Accuracy: Error<±0.35%(>30% of pump stroke)

Rated linear force: 91kg(100% thrust,Wide range of flow velocity)

Thrust regulation: 1~100% arbitrary adjustable

Syringe selection: Built-in main manufacturers, the main model syringe to choose, can use custom syringe, direct input syringe size and diameter

Flow calibration: Through the calibration procedure to obtain more accurate fluid volume

Display: 4.3 inch color LCD with screen display transfusion volume, residual fluid volume, flow, direction, syringe.Animation display

operation status

Operation mode: Touch screen + button

Power-off memory: Storing the running parameters automatically

Communication: RS485,MODBUS Protocol

External control: External signal control start/stop, status signal output

Power supply: AC100~240V,50Hz/60Hz

Environment: Temperature 5~40℃, relative humidity<80%

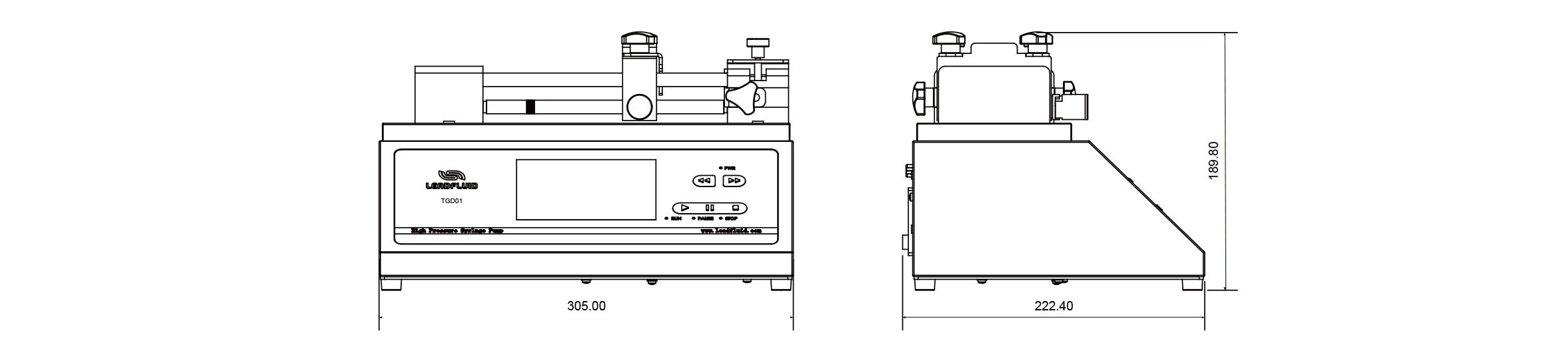

Dimension: 305×222×190 mm

IP grade: IP31

Shell material: Metal with anti-corrosion coating

Weight: 6.6KG

Reference Table of Syringe Specifications and Flow Rate

| Syringe size | Syringe ID (mm) | Min flow rate(nL/min) | Max flow rate(mL/min) |

| 0.5µL | 0.103 | 3.000pL/min | 1.583µL/min |

| 1 µL | 0.146 | 6.027pL/min | 3.181µL/min |

| 2 µL | 0.206 | 11.998pL/min | 6.333µL/min |

| 5 µL | 0.343 | 33.264pL/min | 17.556µL/min |

| 10µL | 0.485 | 66.508pL/min | 35.102µL/min |

| 25µL | 0.729 | 150.261pL/min | 79.305µL/min |

| 50µL | 1.030 | 299.962pL/min | 158.313µL/min |

| 100µL | 1.457 | 600.221pL/min | 316.784µL/min |

| 250µL | 2.304 | 1.501nL/min | 792.152µL/min |

| 500µL | 3.256 | 2.998nL/min | 1.582mL/min |

| 1000 µL | 4.608 | 6.004nL/min | 3.169mL/min |

| 1mL | 4.699 | 6.243nL/min | 3.295mL/min |

| 2.5mL | 4.851 | 6.654nL/min | 3.512mL/min |

| 3mL | 8.585 | 20.839nL/min | 10.998mL/min |

| 5mL | 11.989 | 40.640nL/min | 21.449mL/min |

| 8mL | 9.525 | 25.652nL/min | 13.539mL/min |

| 10mL | 14.427 | 58.850nL/min | 31.060mL/min |

| 20mL | 19.050 | 102.608nL/min | 54.154mL/min |

| 30mL | 21.590 | 131.795nL/min | 69.558mL/min |

| 50mL | 26.594 | 199.968nL/min | 105.538mL/min |

| 100 mL | 34.900 | 344.384nL/min | 181.758mL/min |

| 140 mL | 37.950 | 407.208nL/min | 214.915mL/min |

Syringe Size

| Type | Size |

| Plastic syringe | 1~140mL |

| Micro syringe | 0.5~1000μL |

| Glass syringe | 1~50mL |

| Gas tight syringe | 5~100mL |

| Stainless steel syringe | 8mL 20mL 50mL 100mL Stock inventory |

| (316L syringe,Perfluoro/fluoro rubber seal) | 2.5mL 8mL 20mL customization |

Stainless Steel Syringe

| Syringe size | 8mL | 20mL | 50mL | 100mL |

| ID(mm) | 9.53 | 19.13 | 28.6 | 34.9 |

| OD(mm) | 13 | 22 | 32 | 38 |

| Effective stroke(mm) | 112.4 | 69.6 | 77.83 | 104.5 |

| Effective strokeRated working pressure PN(Mpa) | 12.8 | 4.8 | 4.8 | 4.8 |

| Adapter tube | φ3×0.5 mm | φ6×1.0 mm | φ8×1.0 mm | Φ10×1.5 mm |

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure, in actually it is effected by specific factors such as pressure, medium, etc. Above for reference only.

Dimension (mm)

Statement:The final explanation right of above information belongs to Lead Fluid.