Pump Head Material

Shell: PPS

Card: PPS

Roller: SS304

Roller shaft: SS304

DT10 Flow Parameters

Tube material: Silicone,Pharmed,Viton,Chemical,Tygon 3603,etc.

Wall thickness:0.8~1mm, 13#14# wall thickness:1.6mm

| ID(mm) | 0 .13 | 0.25 | 1 | 2 | 2.4 | 3.2 | 0.8 | 1.6 |

| Tube | 13# | 14# | ||||||

| mL/rpm | 0.0023 | 0.0069 | 0.07 | 0.3 | 0.39 | 0.64 | 0.05 | 0.18 |

| mL/min (Continuous working max 100rpm) | 0.23 | 0.69 | 7.4 | 30 | 39 | 64 | 5 | 18 |

DT15 Flow Parameters

Tube material: Silicone,Pharmed,Viton,Chemical,Tygon 3603,etc.

Wall thickness:1.6mm

| ID(mm) | 2 .4 | 3.1 | 4.8 | 6.4 |

| Tube | 19# | 16# | 25# | 17# |

| mL/rpm | 0.67 | 1.0 | 2.2 | 3.7 |

| mL/min (Continuous working max 600rpm) | 400 | 600 | 1320 | 2240 |

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure, in actually it is effected by specific factors such as pressure, medium, etc. Above for reference only.

Pump Head Specification

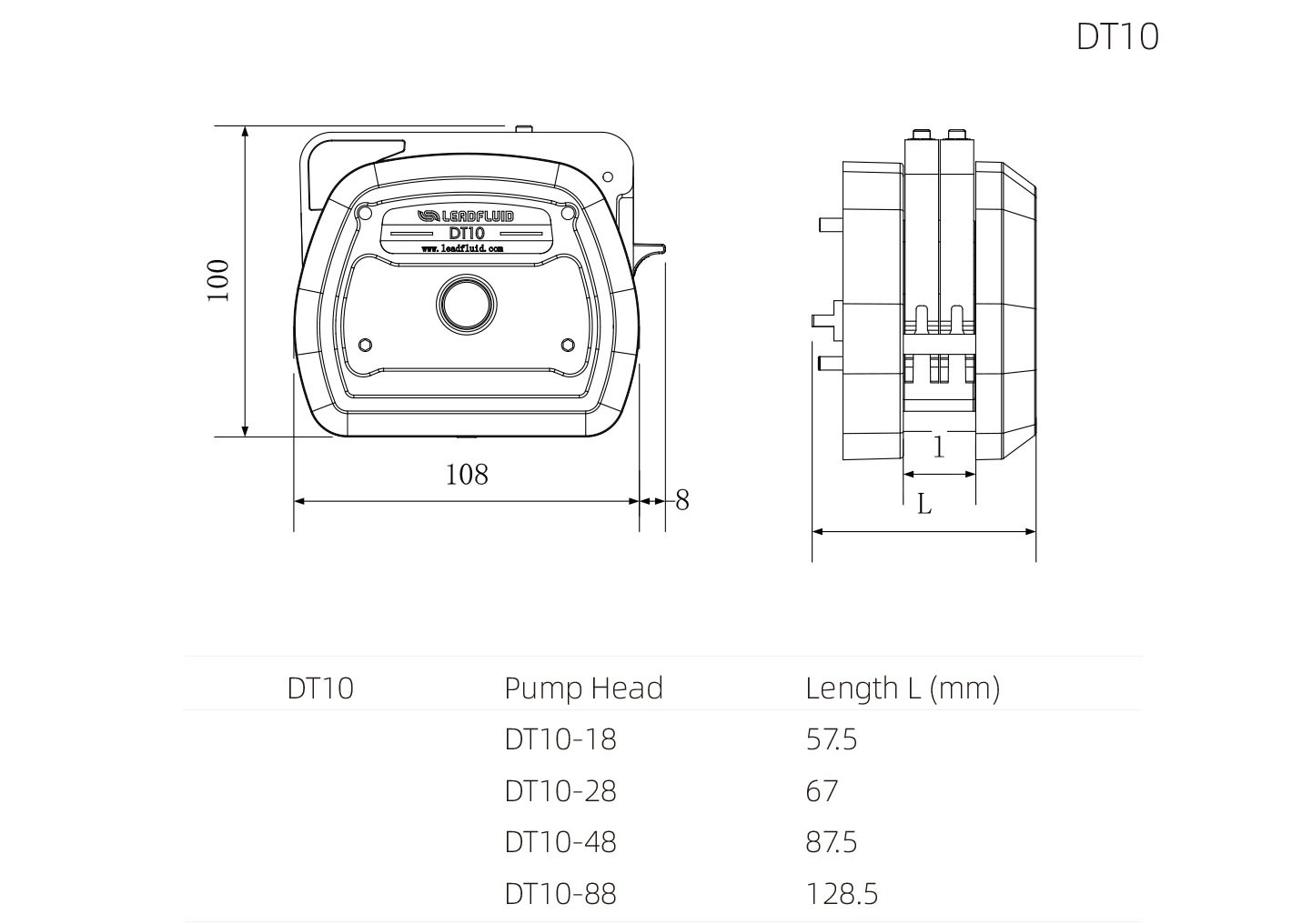

DT10 series

Channel: 1,2,4,8

Roller: 8

Speed range: 0.1~100rpm/min

Flow range: 0.00023~64mL/min

Pressure Tube Clearance: Adjustable

Bear Liquid Temperature: Less than 200℃

Corrosion Resistance: PPS is resistant to most acid, alkali, salt liquids and organic solvents.

Motor: Stepper motor, servo motor ,AC gear motor, DC gear motor etc.

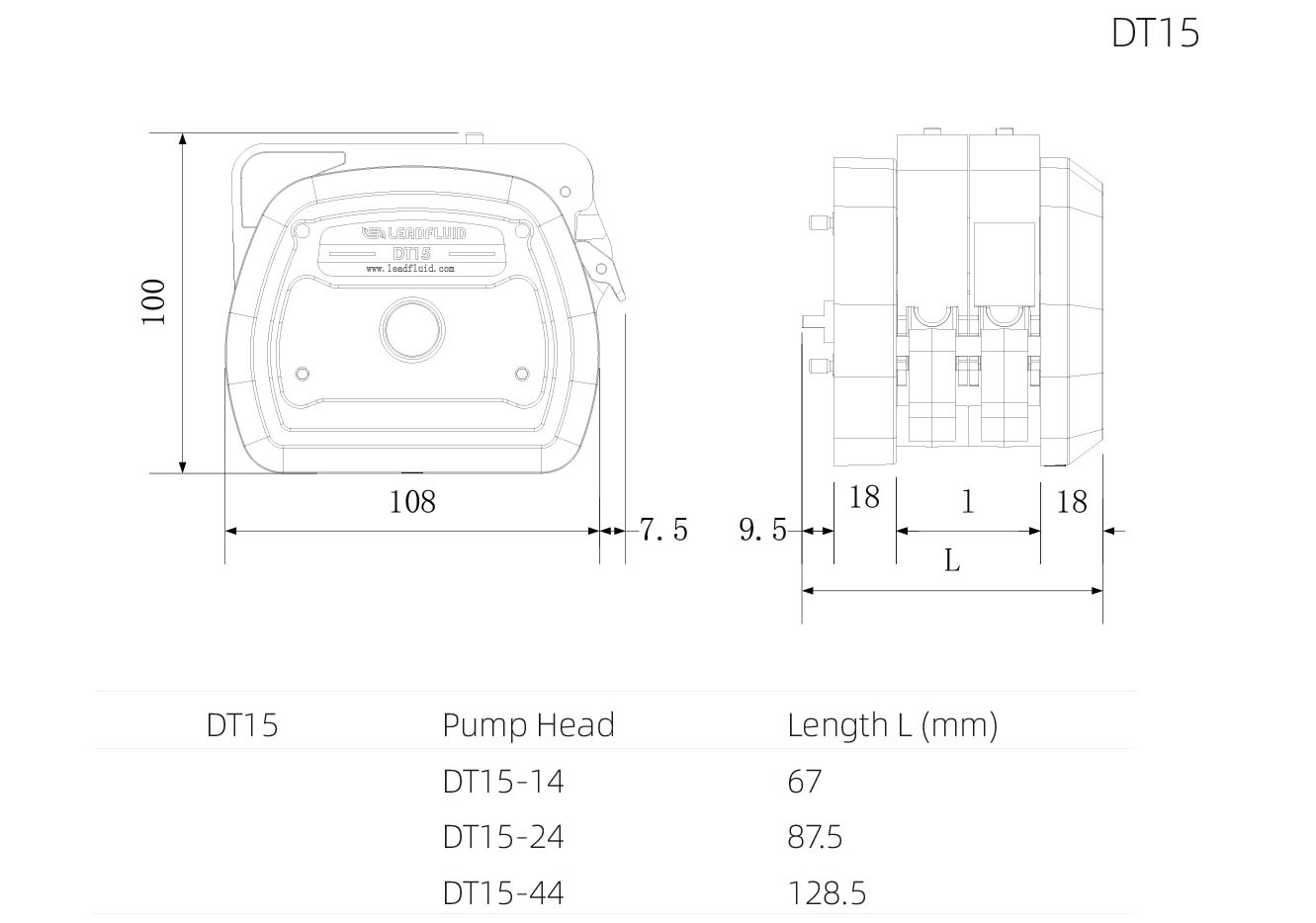

DT15 series

Channel: 1,2,4

Roller: 4

Speed range: 0.1~600rpm/min

Flow range: 0.067~2240mL/min

Pressure Tube Clearance: Adjustable

Bear Liquid Temperature: Less than 200℃

Corrosion Resistance: PPS is resistant to most acid, alkali, salt liquids and organic solvents.

Motor: Stepper motor, servo motor ,AC gear motor, DC gear motor etc.

Dimension(mm)

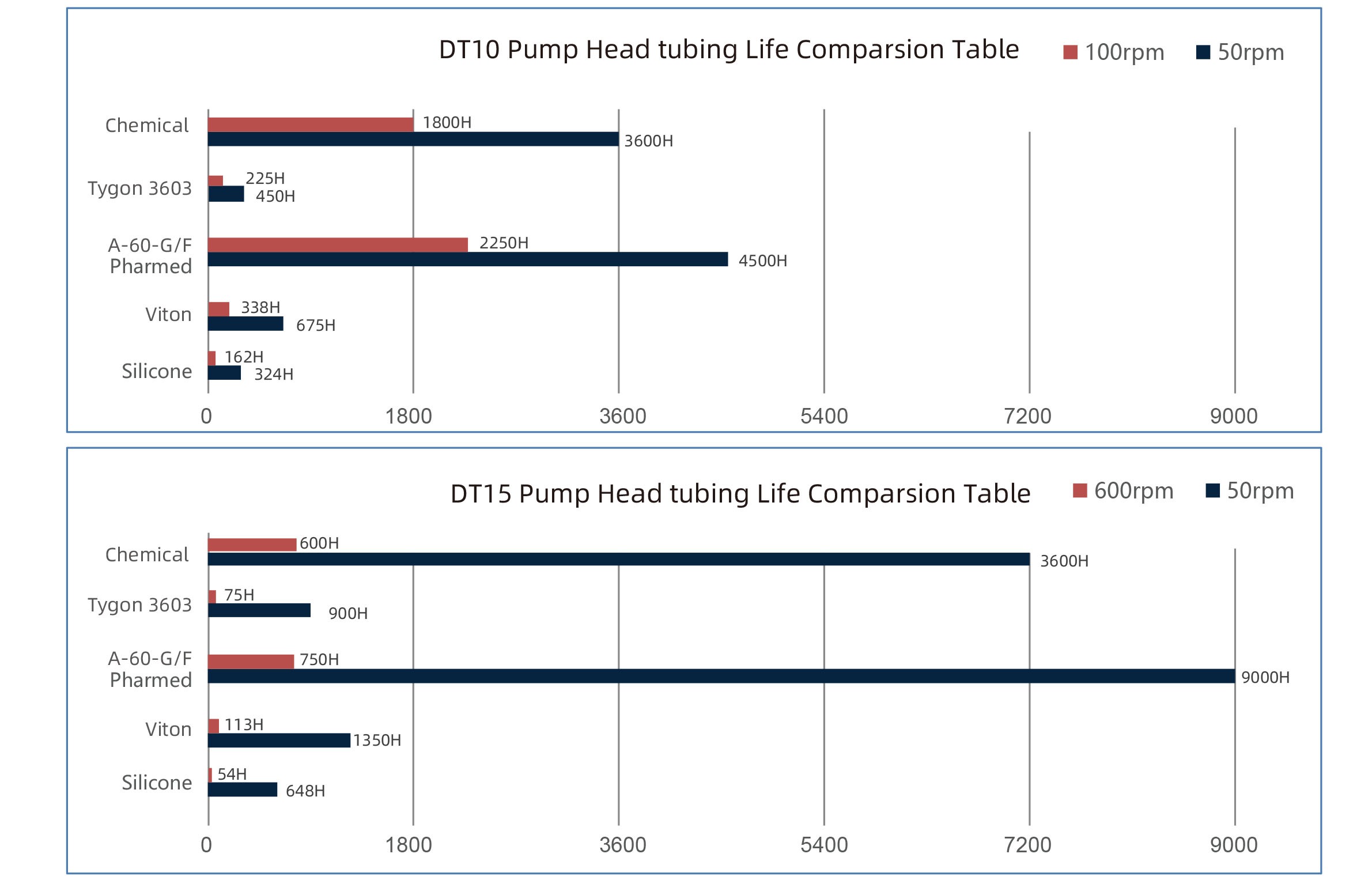

Tube Life Comparison Table

Notes:

The above data are all test results obtained by Lead Fluid laboratory under normal temperature and pressure for the transmission of pure water, which are for reference only; the actual service life may be affected by specific factors such as pressure, temperature, medium characteristics, tube batch and wall thickness; for specific problems, please contact Lead Fluid engineers to get better technical support.

Statement:The final explanation right of above information belongs to Lead Fluid.