Features

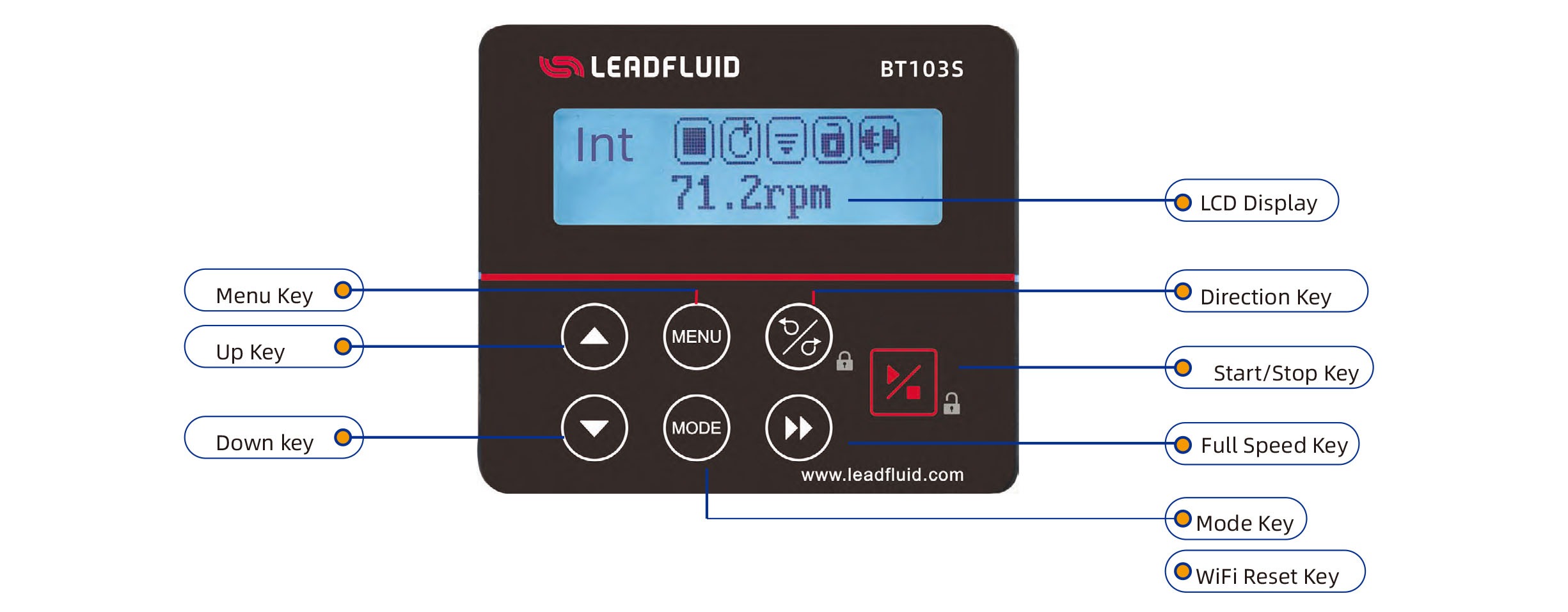

• LF -LED-OS software system, high definition lattice LCD display, switching between Chinese-English,parameter setting simplely, intuitive state display.

• Industrial mask keypad operation, simple and convenient, high durability.

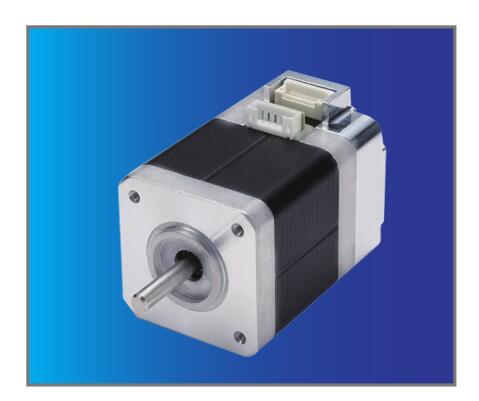

• High quality stepper motor drive, speed precision, running stability,high-precision flow transmission.

• Start/ Stop, adjust speed, reversible direction, full speed and,stat e memory (power-down memory).

• Can set the parameters of running time , interval time and cycle times to meet the requirements of timing, quantitative, liquid dispensing and flow testing.

• Slow speed stop and suction function, which c an effectively prevent the dropping of liquid when the machine stops.

• Keypad locked function to prevent mis-operation.

• Streamline injection molding shell design, simple, beautiful and easy to clean.

• The circuit board with conformal coating makes it dust-proof and moisture-proof.

• Super anti-interference feature, wide input voltage range, acceptable for complex power environment.

• External analog adjust speed , external control start-stop ,reversible direction, external control signal physical isolation.

• RS485 communication interface, Modbus protocol is available , support setting communication parameters, easy to connect with various control devices.

• Can match various high performance pump head, realize different pump head and drive combination.

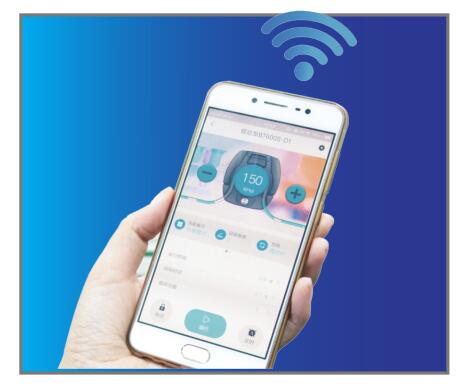

• The remote start-stop, adjust speed and timing operation can be realized through Lead Fluid APP software. It also has monitoring functions such as stop alarm, change o f pump tube (optional).

• Support blocking turn alarm, leak age alarm (optional).

• Thermal printer can be connected, real-time printing operation parameters (optional).

Technical Parameter

Flow range: 0.00011~500mL/min

Speed range: 0.1~100.0rpm

Speed resolution: 0.1rpm

Speed accuracy: <±0.2%

Dispensing volume: 0.1~999.9 S/Min/H, time unit adjustable

Dispensing time: 0.1~999.9 S/Min/H, time unit adjustable

Dispensing interval time: 1~999,“0”Infinite cycle

External control signal input: (1) Start/Stop: passive contact, external control input level (5~24V);(2) Forward/Reverse: passive contact, external control input level (5~24V);(3) Speed Regulation: analog 0~5V, 0~10V, 4~20mA can be set

External control signal output: (1) Start/Stop: Level Signal (following input voltage);(2) Forward/Reverse: Level Signal (following input voltage)

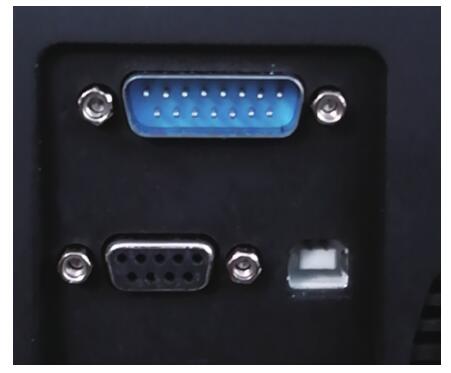

Communication interface: RS485, MODBUS protocol is available, DB15 external control interfacePower supply:AC100~240V ,50Hz/60Hz

Power consumption: <30W

Working environment: Temperature 0 ~ 40℃, relative humidity<80%

IP grade: IP31

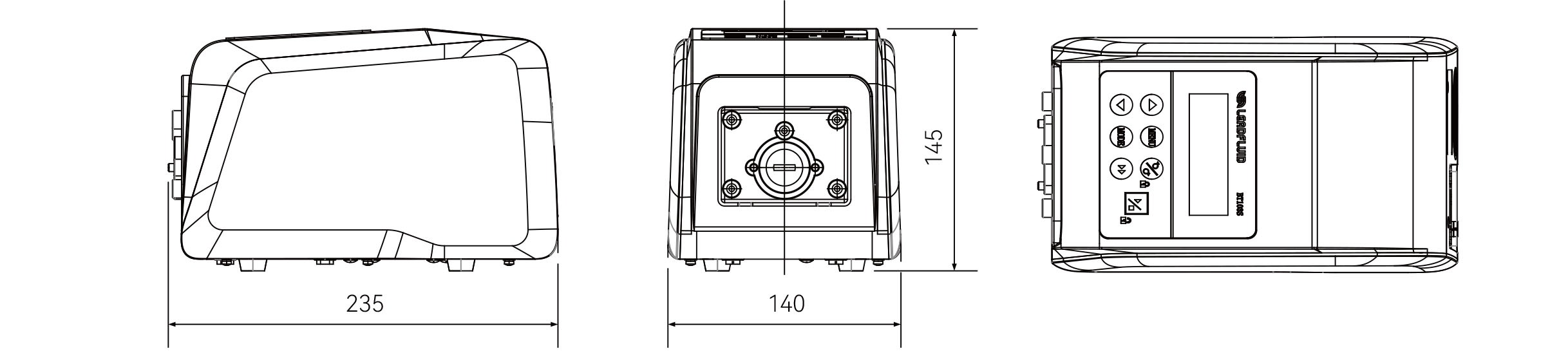

Dimension(L×W×H): 235x140x145mm

Weight: 2.8kg

BT103S Applicable Pump Head and Tube, Flow Parameters

| Drive Type | Pump Head | Channel | Tube(mm) | Single Channel Flow Rate (mL/min) |

| BT103S | DG/DS (6 rollers) | 1,2,4 | Wall 0.8~1mm, ID≤3.17mm | 0.00016~49 |

| DG/DS (10 rollers) | 1,2,4 | Wall 0.8~1mm, ID≤3.17mm | 0.00011~32 | |

| YZ15/YZ15T | 1 | 13#14#19#16#25#17#18# | 0.005~427 | |

| YT25 | 1 | 114#116#15#24#35#36# | 0.024~500 |

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure, in actually it is effected by specific factors such as pressure, medium, etc. Above for reference only.

Dimension(mm)

Application Fields:

Modern Laboratories, Industrial Production, Medical Equipment, and other sectors

Typical Applications:

Material transfer and preparation, TFF/DFF ultrafiltration, Fluidized beds, Additives

Statement: The final explanation right of above information belongs to Lead Fluid.