Introduction

•The series includes three models: B350K1BZ25-24, B350K2BZ25-24, and B350K3BZ25-24.

•External analog quantity to adjust the speed, analog quantity 0-5V/0-10V/4-20mA.

•External signal controls start and stop, forward and reverse rotating, external control signal 12-24V wide range input, optoelectronic isolation.

•Small and compact with an attractive and aesthetically pleasing design;

•Quiet operation;

•The pump head shell is made of transparent polycarbonate (PC), allowing the internal operation to be observed during functioning;

•The roller is made from S304 stainless steel, known for its corrosion resistance;

•Ideal for continuous operation at high speeds;

•General installation size, can be used in cascade;

•Perfect for small to medium flow applications, this equipment can be seamlessly integrated with devices, instruments, and laboratory setups.

Parameters

Motor types: 57 stepper motor

Power supply voltage: DC 24-36V

Control mode: External analog

External Control Functions: Analog quantity 0-5V/0-10V/4-20mA corresponding to the adjustable speed range 0-350rpm;External level signal controls the start, stop, and direction of the motor.

Speed range: ≤350rpm

Flow rang: ≤910mL/min

Channel number: 1 Channel

Roller number: 3 Rollers

Running direction: Clockwise/Counterclockwise rotation

Tube material: Silicone Tube, Pharmed, A-60-G

Tube installation method: Built-in tube

Tube pressure types: Fixed gap

Pump head shell material: PC

Material of the pump head rollers: S304 stainless steel

Tube life: ≥4000h

Noise: ≤ 60db (testing environment noise ≤40dB, horizontal distance between test product and noise meter is 1 meter)

Driver weight: 1.683kg (Without Tube)

Dimensions (L*W*H): 213*116*74(mm)

Wattage: ≤30W

Working environment: Temperature 0- 40°C, , Relative humidity< 85% RH

Storage environment: In a clean and well-ventilated environment with ambient temperatures ranging from -40 to +50°C, and relative humidity not exceeding 95%, the air must not contain corrosive, flammable gases, oil mist, or dust.

Tube Model and Flow Reference Table

| Model | Tube Material | Tube No. | mL/rpm | 10pm | 100pm | 350pm |

| B350K1BZ25-24 | Silicone | 24# | 2.6 | 26 | 260 | 910 |

| B350K2BZ25-24 | ||||||

| B350K3BZ25-24 |

•The above flow data were all tested using a Lead Fluid silicone tube to pump pure water under laboratory conditions with normal temperature and pressure. This data is for reference only.

•Due to pressure in actual use , temperature, medium characteristics, tube material and other specific factors, the specific situation needs to consult our engineers.

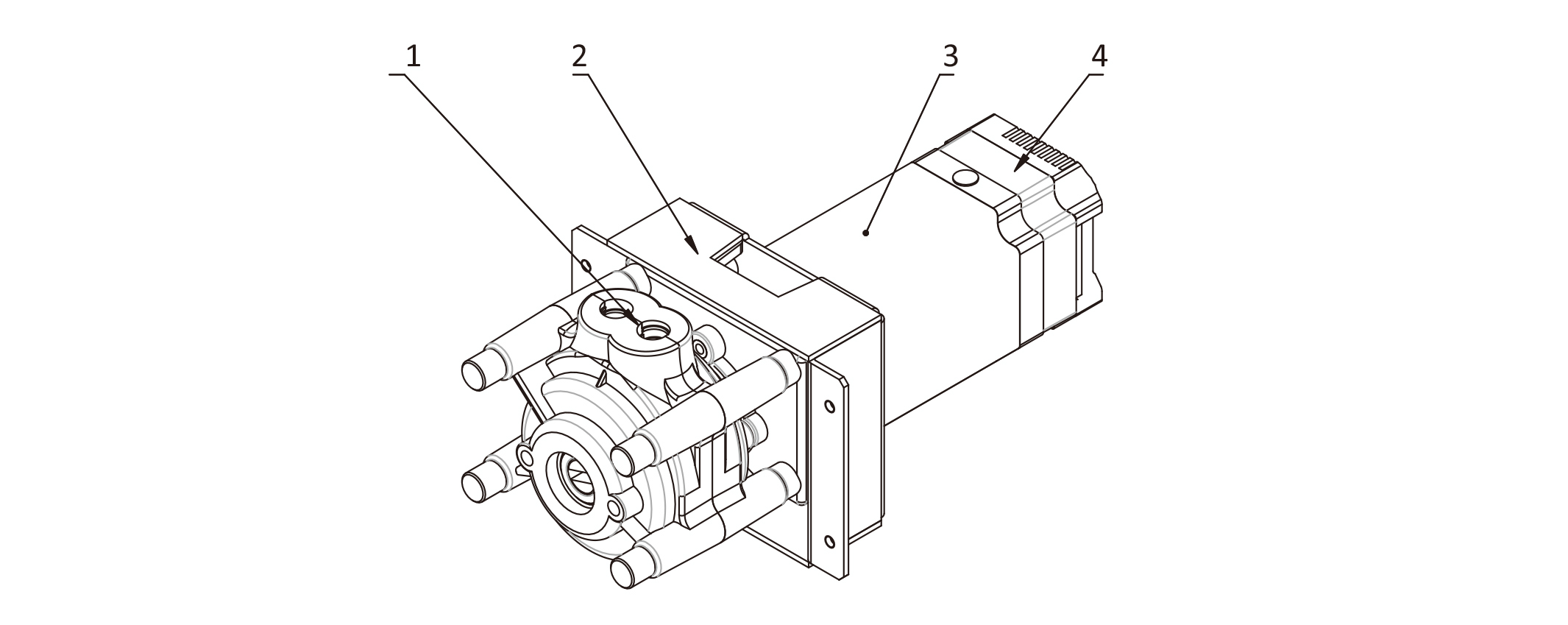

Head Pump Structure

Component name and function:

1.Pump head: Install tube-lines to transport liquid

2.Mounting Plate: Connects the motor and pump head bracket, and can also be used to install the product onto other equipment.

3.Motors: Providing Power

4.Control and drive unit: External analog control.

Note: A pump tube pressure lever, a 200mm silicone tube, and four single-channel installation screws are included with the product.

Figure 1 Products Structure

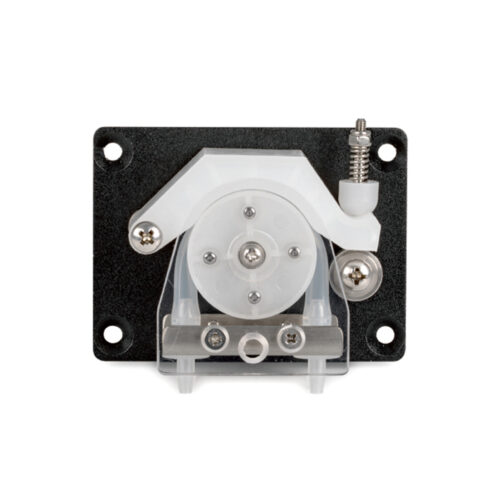

Tube Installation

• Press down on the clip to open the pump head shell. Open the clamp to place the tube inside the pump head. Once the tube is properly installed, close the pump head shell.

Figure 2 Pump Head Structure Diagram Figure 3 Tube Pressure Lever

Usage Method

Tube Installation

• Open the pump head shell and use a tube pressure lever to secure the tube at the illustrated position.

• Turn the tube lever counterclockwise and insert the tube between the roller and the pump shell.

• After fastening the other pump shell, use a tube lever to rotate the main shaft following the instructions in the diagram, and adjust the tube position inside the shell.

Figure 4 Tube Installation Diagram (1) Figure 5 Tube Installation Diagram (2) Figure 6 Tube Installation Diagram (3)

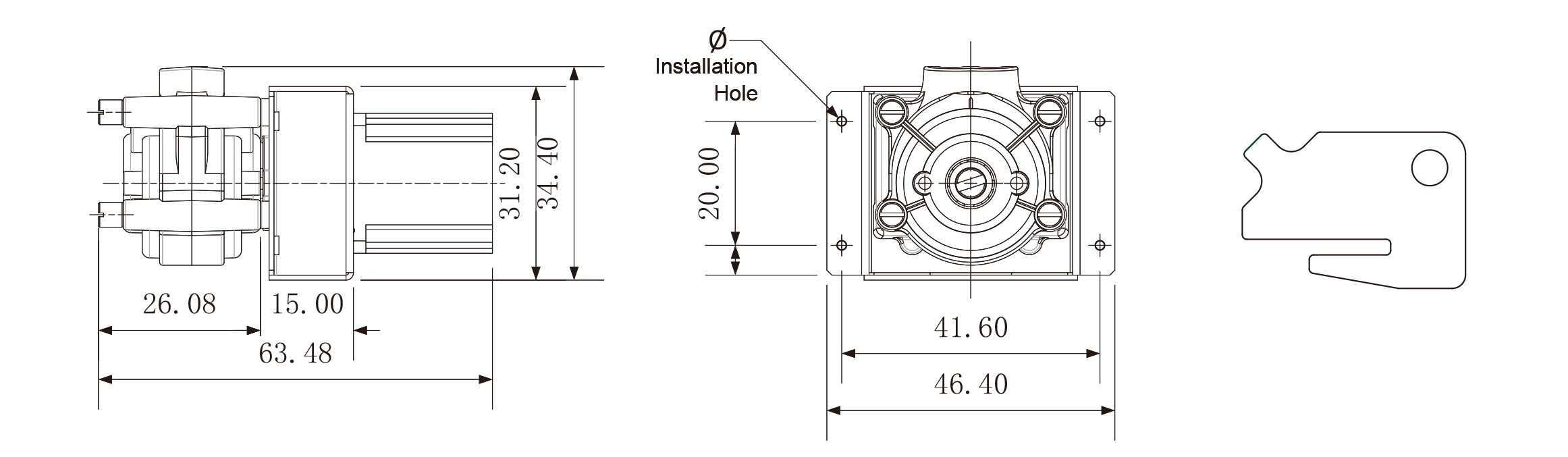

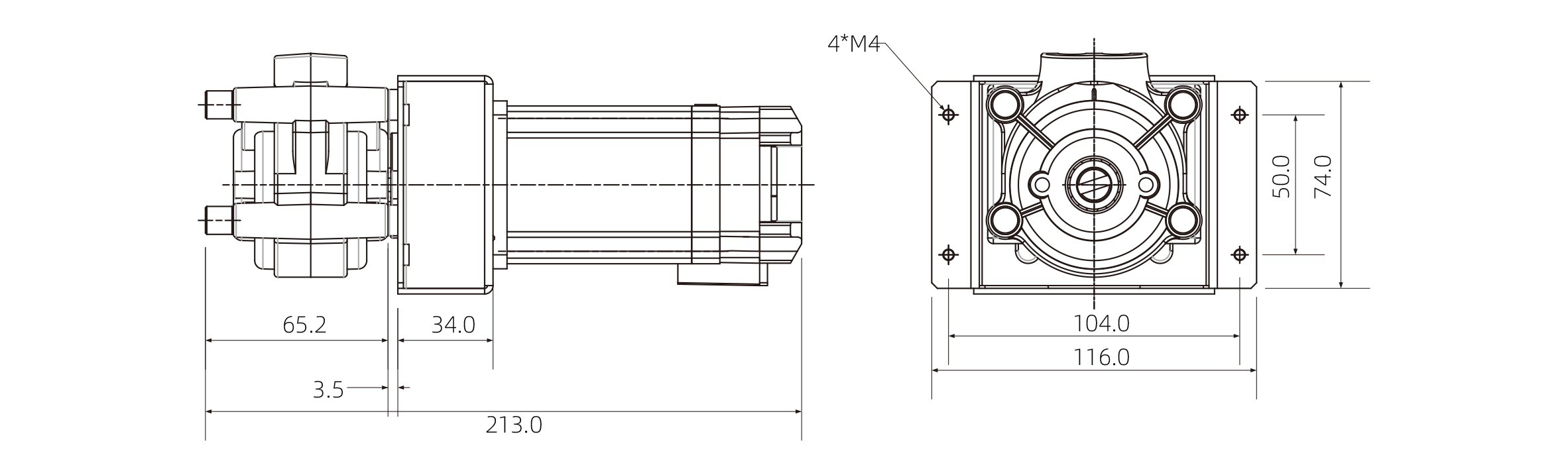

Dimension(mm)