Introduction

• This product has a small size, compact structure, beautiful appearance and

excellent performance.

• The pump head shell is made of engineering plastics with high strength and

corrosion resistance.

• Transparent protective gland made of PC material at the front end for easy

observation of the internal operating state of the pump head.

• The protective gland is connected with the tube bayonet, which is firmly mounted and easy to dismantle.

• It is suitable for ODM matching of various instruments and equipments.

Parameters

Motor Type: 42 stepper motor

Drive and Control Method: Customer provided

Speed Range: ≤300rpm

Flow Range: ≤498mL/min

Channel Number: 1

Number of Rollers: 4 rollers (2 auxiliary rollers)

Rotation Direction: Clockwise/Counterclockwise rotation

Material of Tube: Silicone tube, Pharmed, A-60-G, A-60-F

Method of Tube Installation: Tube connectors

Pressure Tube Type: Fixed clearance

Pump Head Shell Material: PPS

Pump Head Cover Material: PC

Pump Head Roller Material: PVDF

Pump Head Life: ≥1500h

Noise: ≤60dB (test environment noise ≤40dB, test product and noise meter horizontal distance of 1 meter)

Weight: 0.421kg (without tube)

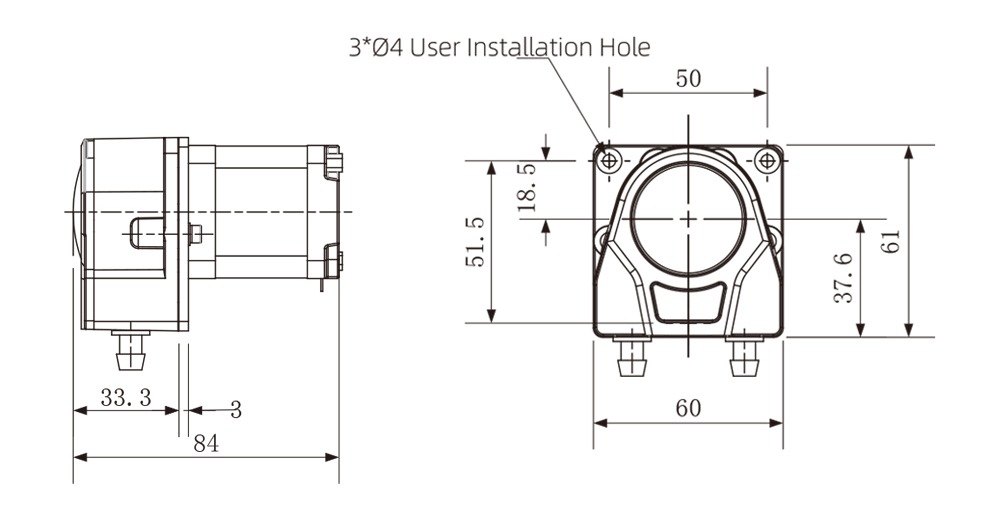

Dimensions: (L×W×H) 84*60*61(mm)

Working environment: Temperature 0- 40°C, relative humidity<85% RH

Storage Environment: Ambient temperature of -40 ~ +50 °C, relative humidity of not more than 95% of the clean and well-ventilated environment, the air shall not contain corrosive, flammable gases, oil mist, dust.

Suitable Tube Model and Flow Rate Reference Table

Flow Rate Table (Unit: mL/min)

| Model | Material of Tube | Suitable Tube | 10rom Flow Rate | 50rpm Flow Rate | 100rpm Flow Rate | 300rpm Flow Rate |

| B300K0KJ15 | Silicone tube | 13# | 0.4 | 2 | 4 | 12 |

| 14# | 1.5 | 7.5 | 15 | 45 | ||

| 19# | 3.2 | 16 | 32 | 96 | ||

| 16# | 5.3 | 26.5 | 53 | 159 | ||

| 25# | 9.5 | 47.5 | 95 | 285 | ||

| 17# | 17 | 83 | 166 | 498 |

For speeds above 100rpm, it is recommended to use intermittent operation. The intermittent operation mode involves running for 0.7 seconds and then stopping for 0.3 seconds.

•The above data is obtained from the test of purified water with a Lead Fluid tube under normal and pressure conditions in the laboratory. This data is for reference only.

•Due to pressure in actual use, temperature, medium characteristics, tube material and other specific factors, the specific situation needs to consult our engineers.

Product Structure & Usage Method

Product Structure

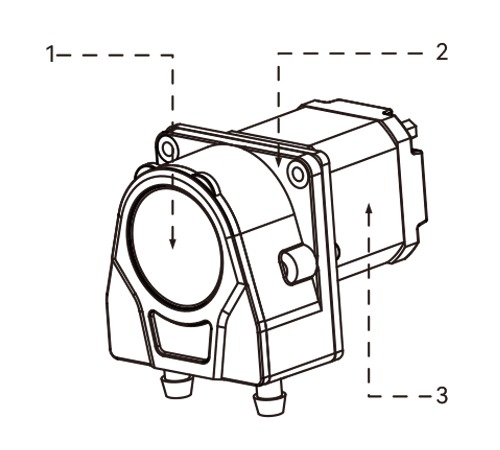

Component Name and Function:

1.Pump Head: Installation of a tubeline to transfer liquid.

2.Mounting Plate: Connects the motor to the pump head bracket and allows the

product to be installed on other devices.

3.Motor: Provides power.

Usage Method

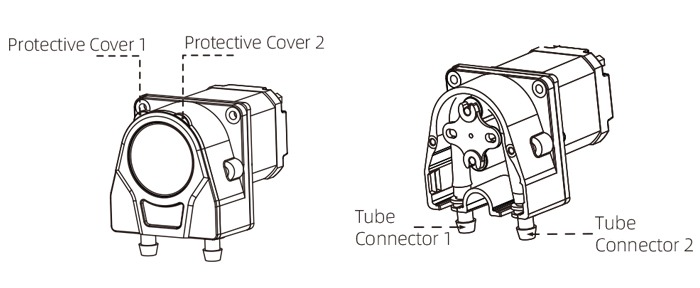

Disassembly of KJ15 Pump Head

Step 1: Pull the protrusion of the protective cover in the direction of the arrow

as shown to remove the protective cover.

Step 2: After the cover is removed, remove the tube connector 1 and tube connector

2 first and then remove the tube as a whole.

Install KJ15 Pump Head

Reverse the order of disassembly.