Introduction

•This series of products consists of three models: B250K1KT15, B250K2KT15, and B250K3KT15;

•External analog quantity to adjust the speed, analog quantity 0-5V/0-10V/4-20mA.

•External signal controls start and stop, forward and reverse rotating, external control signal 12-24V wide range input, optoelectronic isolation.

•The unique design of the spring roller body allows it to adapt flexibly to hoses of varying wall thicknesses, ensuring longer tube lifespan and making installation a breeze;

•The pump head is strong, tough, and highly resistant to chemical corrosion;

•Operates stably and quietly, with a semi-transparent shell that allows for real-time observation of its internal workings;

•Used in medium traffic environments;

•Suitable for use with devices, instruments, and laboratory setups.

•Ideal for integration with OEM systems.

Parameters

Motor types: 57 stepper motor

Power supply voltage: DC 24-36V

Control mode: External Analog

External control functions: The analog signal of 0~5V/0~10V/4~20mA corresponds to an adjustable speed range from 0 to 250 rpm; External level signals control the start, stop, and direction of the motor

Speed range: ≤250rpm

Flow rang: ≤638mL/min

Channel number: 1 Channel

Roller number: 4 rollers (2 main rollers + 2 auxiliary rollers)

Running direction: Clockwise rotation

Tube materials: Silicone tube

Tube installation method: Tube Joint

Tube pressure type: Fixed Gap

Materials of the pump head components: Roller Main Body: PES Shell: PC Base Shell: PPS Roller Shaft: S30408 Stainless Steel

Pump head life: ≥1400h

Noise: <60dB

Driver weight: 0.758kg

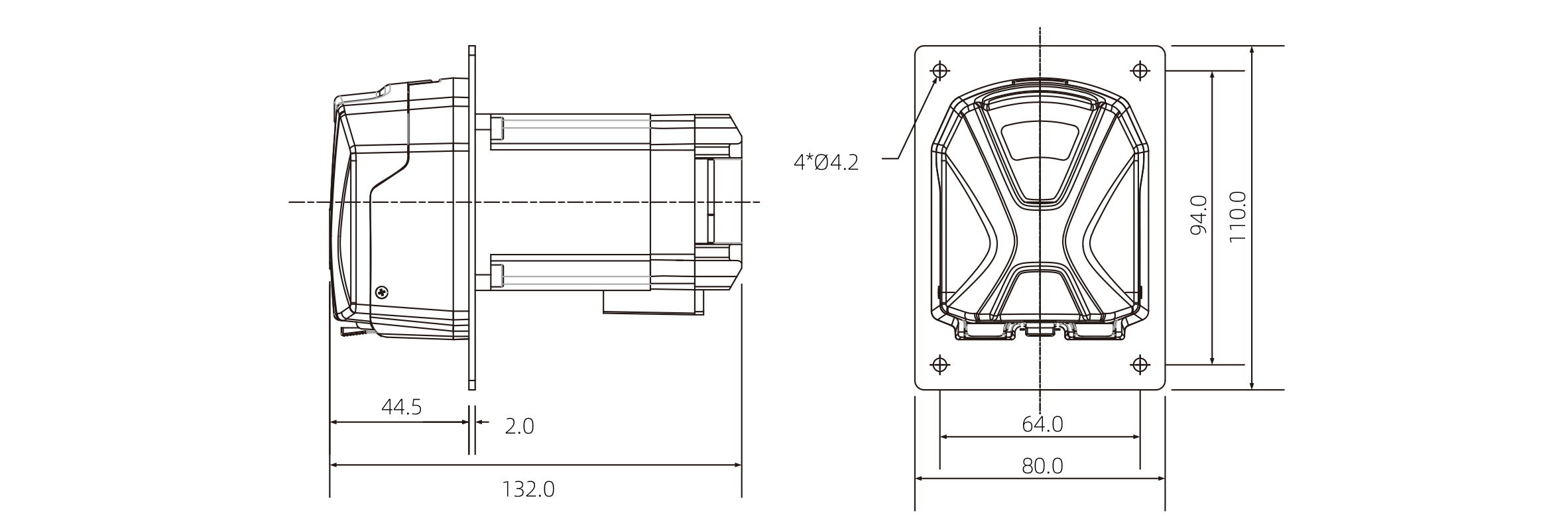

Dimensions(L*W*H): 132*80*110(mm)

Wattage: ≤30W

Working environment: Temperature 0- 40°C, , Relative humidity< 80% RH

Storage environment: In a clean and well-ventilated environment with ambient temperatures ranging from -20 to +50°C, and relative humidity not exceeding 95%, the air must not contain corrosive, flammable gases, oil mist, or dust.

Tube Model and Flow Reference Table

| Model | Tube Material | Tube No. | mL/rpm | 10pm | 100pm | 250rpm |

| B250K1KT15 B250K2KT15 B250K3KT15 |

Silicone tube | 13# | 0.06 | 0.6 | 6 | 15 |

| 14# | 0.24 | 2.4 | 24 | 60 | ||

| 19# | 0.45 | 4.5 | 45 | 112.5 | ||

| 16# | 0.6 | 6 | 60 | 150 | ||

| 25# | 0.95 | 9.5 | 95 | 285 | ||

| 17# | 2.5 | 25 | 255 | 638 |

•The above flow data were all tested using a Lead Fluid silicone tube to pump pure water under laboratory conditions with normal temperature and pressure. This data is for reference only.

•Due to pressure in actual use , temperature, medium characteristics, tube material and other specific factors, the specific situation needs to consult our engineers.

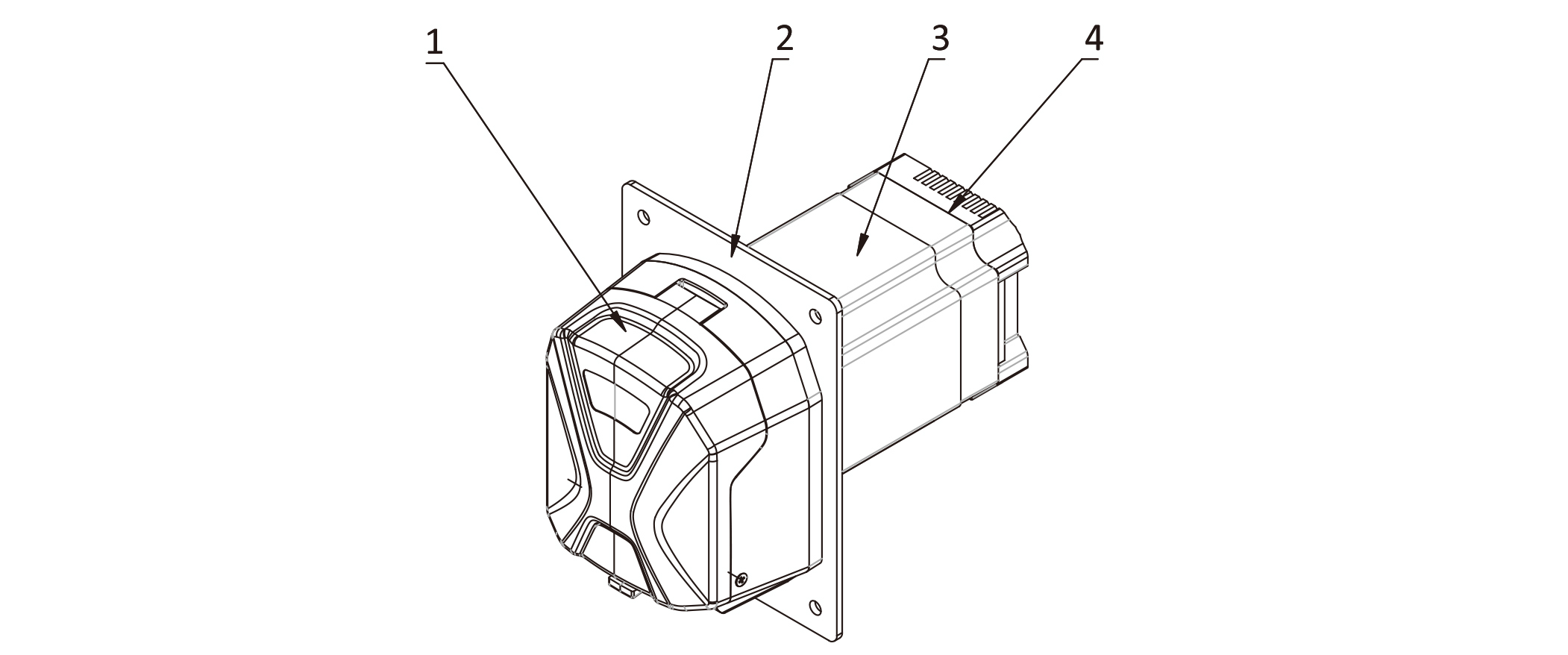

Head Pump Structure

Component name and function:

1.Pump head: Install tubes to transfer liquids.

2.Mounting Plate: This component connects the motor to the pump head and allows the product to be installed onto other devices.

3.Motor: Provides power.

4.The drive control unit: manages the stepper motor’s speed and start/stop settings.

Figure 1 Products Structure

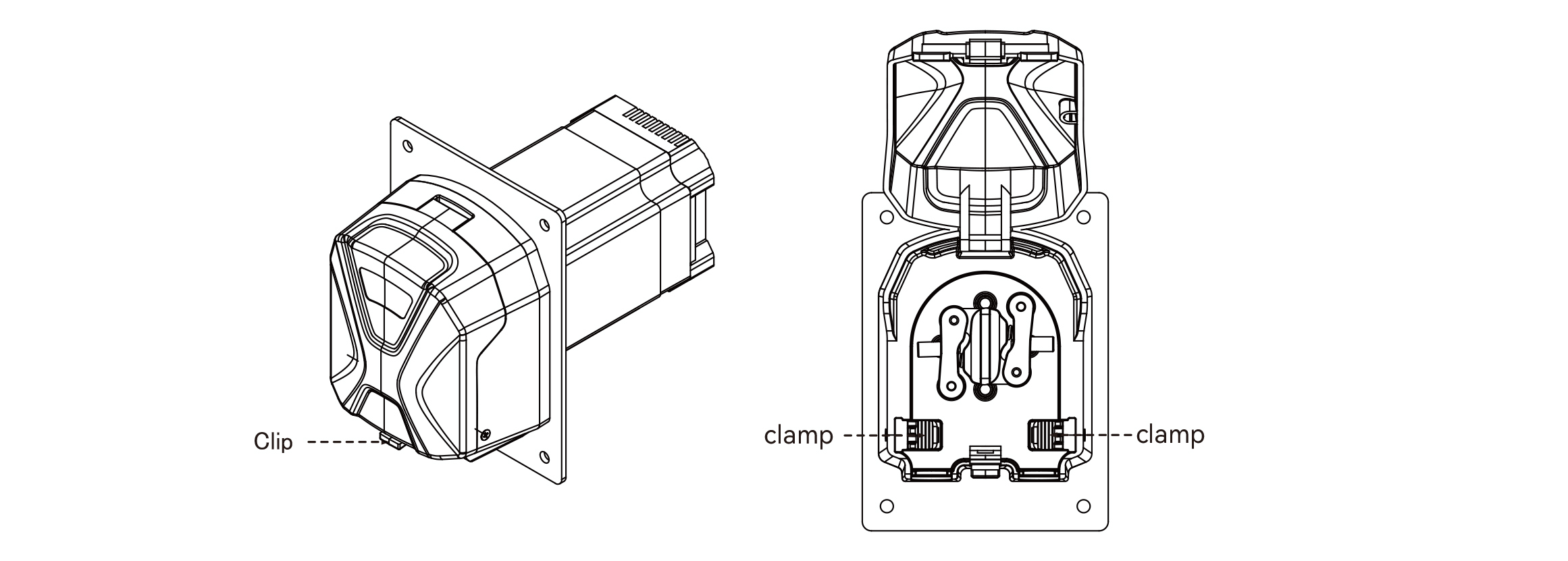

Tube Installation

• Press down on the clip to open the pump head shell. Open the clamp to place the tube inside the pump head. Once the tube is properly installed, close the pump head shell.

Figure 2 Tube Installation Diagram

Dimension(mm)