Introduction

• This series of products includes three models: B200K1KJ15, B200K2KJ15, and B200K3KJ15;

• External analog quantity regulates the speed, analog quantity 0-5V/0-10V/4-20mA;

• External signal controls start and stop, forward and reverse rotating, external control signal 12-24V wide range input, optoelectronic isolation.

• This product has a compact structure, an attractive appearance, and excellent performance;

• The pump head shell is made of high-performance engineering plastic, which has high strength and strong corrosion resistance;

• The transparent protective cover made of PC material on the front end allows easy observation of the pump head’s internal operating status;

• The protective gland is connected to the housing with a bayonet lock, ensuring a secure fit and easy disassembly;

• Applicable to ODM support for various instruments and equipment.

Pump Parameters

Motor Types: 42 stepper motor

Power Supply Voltage: DC 12-24V

Control Mode: External control analog quantity

External Control Functions: The analog quantities 05V/010V/4~20mA correspond to a speed regulation range of 0-200 rpm, and the external level signal controls the motor’s start, stop, and direction.

Speed Range: ≤200rpm

Flow Rang: ≤190mL/min

Channel Number: 1 channels

Roller Number: 4 Rollers (2 Auxiliary Rollers)

Running Direction: Clockwise/Counterclockwise rotation

Suitable Tubes: Wall thickness: 1.6mm, inner diameter: 0.8\1.6\2.4\3.2\4.8mm

Tube Material: Silicone tube, Pharmed, A-60-G, A-60-F

Tube Installation Method: Tube Connector

Pump Head Component Material: PPS, PC, PVDF

Pump Head Life: ≥1500h

Noise: ≤60dB

Driver Weight: 0.421kg

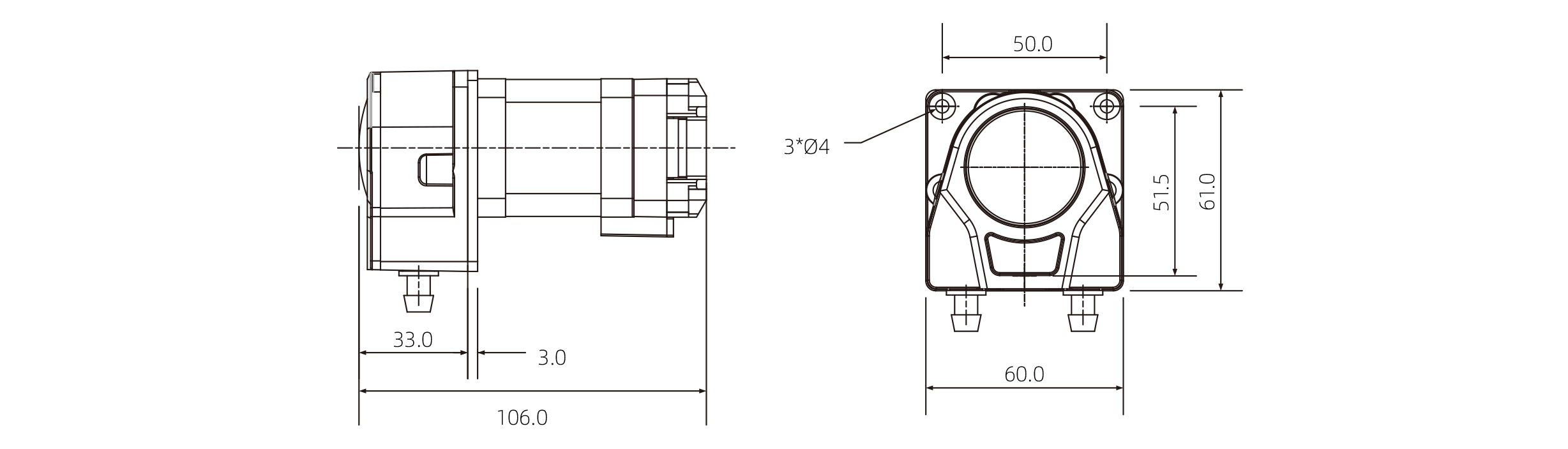

Dimensions: (L*W*H)106*60*61(mm)

Power: <30W

Working Environment: Temperature 0- 40°C, , Relative humidity< 85% RH

Storage Environment: In a clean and well-ventilated environment with ambient temper-atures ranging from -40 to +50°C, and

relative humidity not exceeding 95%, the air must not contain corrosive, flammable gases, oil mist, or dust.

Tube Model and Flow Reference Table

| Model | Tube Material | Tube No. | Flow Rate (mL/min) | |||

| 1rpm | 10rpm | 100pm | 200pm | |||

| B200K1KJ15 B200K2KJ15 B200K3KJ15 |

Silicone | 13# | 0.04 | 0.4 | 4 | 8 |

| 14# | 0.15 | 1.5 | 15 | 30 | ||

| 19# | 0.32 | 3.2 | 32 | 64 | ||

| 16# | 0.53 | 5.3 | 53 | 106 | ||

| 25# | 0.95 | 9.5 | 95 | 190 | ||

•The above flow data were all tested using a Lead Fluid silicone tube to pump pure water under laboratory conditions with normal temperature and pressure. This data is for reference only.

•Due to pressure in actual use , temperature, medium characteristics, tube material and other specific factors, the specific situation needs to consult our engineers.

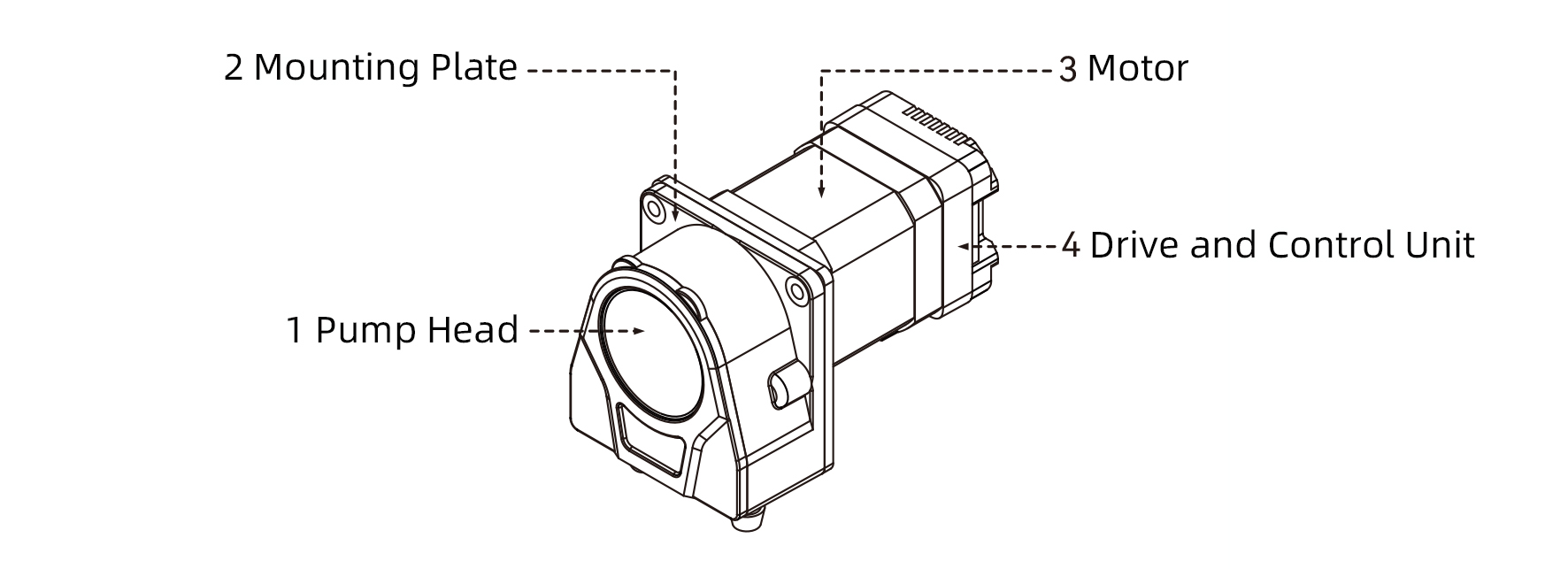

Head Pump Structure

Component Names and Functions:

1. Pump Head: Install the pipeline to transport liquid;

2. Mounting Plate: Connects the motor to the pump head bracket and allows the product to be installed on other equipment;

3. Motor: providing power;

4. Drive and Control Unit: The external control analog quantity controls the motor speed and start/stop.

Figure 1 Diagram of Product Structure

Usage Method

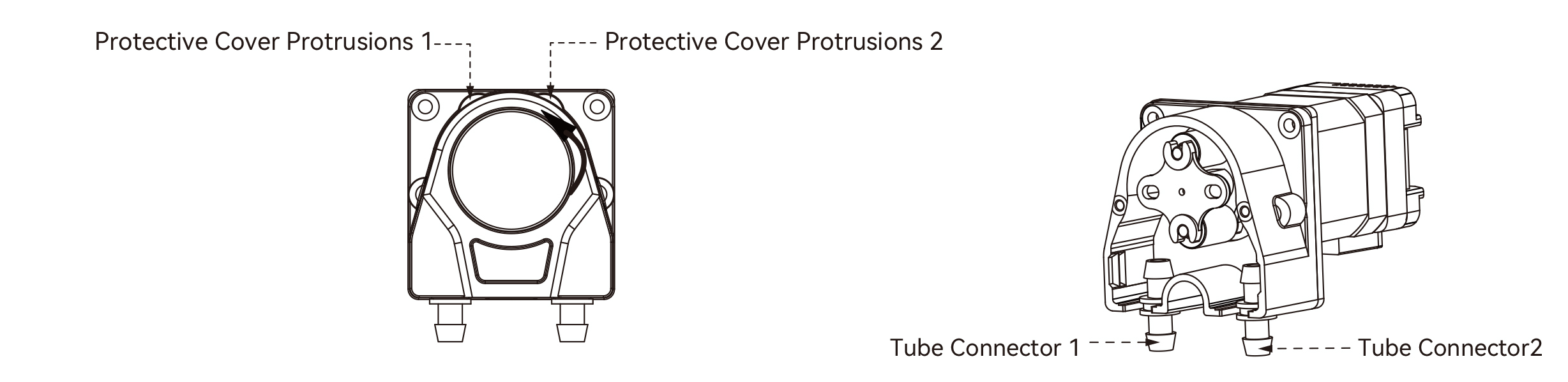

Disassembling the KJ15 pump head

Step 1: As shown in the figure, first open the protective cover protrusions 1 and 2, and then the protective cover can be removed.

Step 2: After removing the protective cover, first remove tube connector 1 and tube connector 2, then the entire tube-line can be removed.

Figure 2: A diagram of the shell disassembly Figure 3 Diagram of tube-line disassembly