Practice is the sole criterion for testing truth; experiments are an important means of verifying product performance! The Pump Laboratory series strives to comprehensively showcase product performance through scientific enterprise standards, rigorous experimental methods, and precise experimental data. In this issue, we focus on the FT1505 pump head, conducting in-depth tests and interpretations of its core performance across multiple dimensions, from flow stability to flow variation.

Flow Stability

Experimental Background

In high-precision scenarios such as scientific research and pharmaceutical processes, the stability of flow directly affects the reliability of experimental results and process consistency. Particularly, the negative pulsation (short-term decline or even backflow of flow) can adversely impact precise delivery and equipment lifespan.

Experimental Data

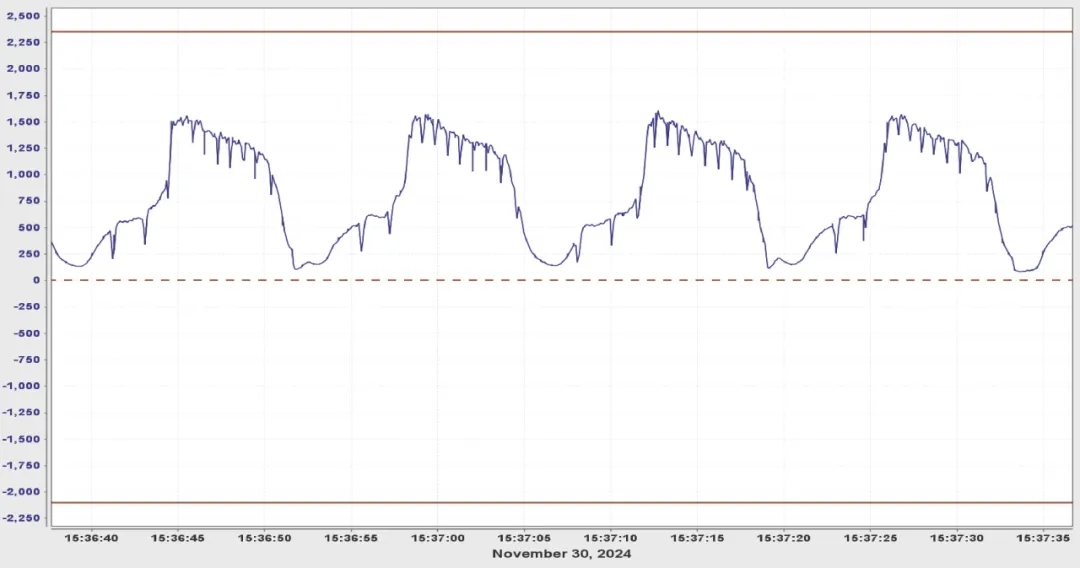

Figure: Instantaneous Flow Pulsation Curve of FT1505

Note: Under standard conditions, with a 25# silicone tube and a speed of 1 rpm, flow data was collected for 59 seconds.

The figure shows the instantaneous flow curve of FT1505 during operation. The curve exhibits periodic fluctuations, which is a normal phenomenon determined by the working principle of the pump head rollers pressing the hose. The overall flow remains in the positive range, with no negative fluctuations (backflow) observed, and the amplitude of fluctuations is small, demonstrating good flow output consistency.

Data Interpretation

• Risk of Negative Pulsation

→ Decrease in Delivery Precision: In scenarios with stringent flow control requirements (such as pharmaceuticals and scientific research), fluctuations directly affect ratios and experimental outcomes.

→ Impact on Equipment Lifespan: Frequent fluctuations exacerbate wear on the hose and pump head, leading to increased maintenance costs.

• FT1505 achieves stable flow output, providing a reliable solution for high-precision and high-stability delivery scenarios.

Flow Variation

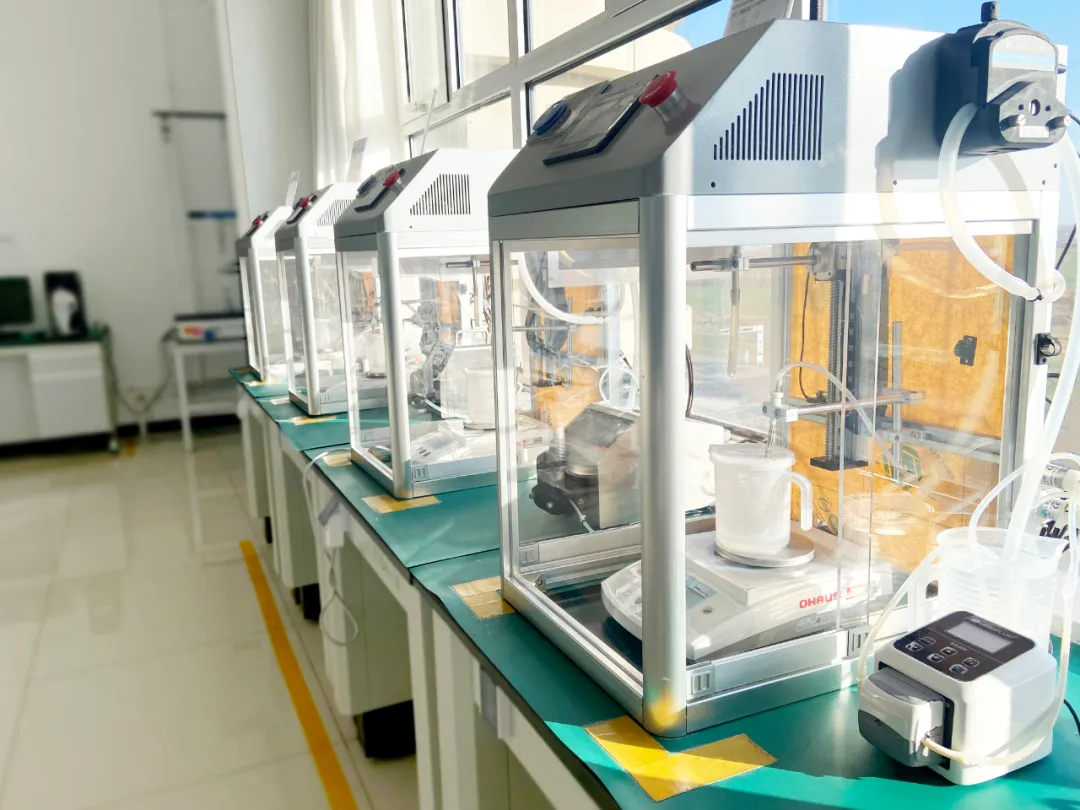

(The BQ80S + FT1505 pump is being tested through a flow automatic detection device for tube lifespan and flow variation)

Experimental Background

Flow variation assesses the changes in the transmission performance of the pump tubing under continuous pressure from the pump head. It is a key indicator for measuring the compatibility and lifespan of the pump head with the tubing, directly affecting equipment maintenance cycles and operating costs.

Experimental Data

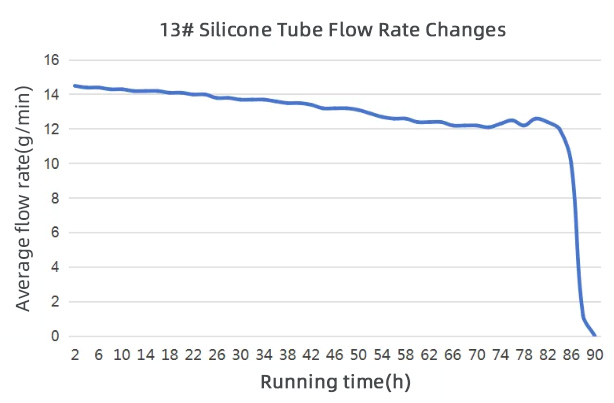

Note: With a 13# silicone tube, it operates continuously at a speed of 400 rpm, recording flow variations until the hose fails.

Note: With a 25# silicone tube, it operates continuously at a speed of 400 rpm, recording flow variations until the hose fails.

Data Interpretation

The FT1505 demonstrates extended operational duration and stable flow output under both flow specifications, effectively reducing maintenance frequency and operational costs, suitable for scenarios requiring continuous operation.

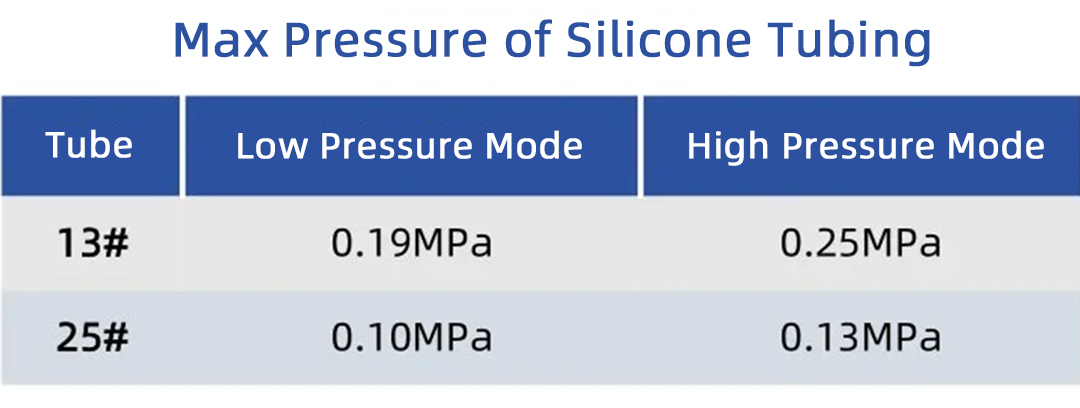

Pump Head Pressure

Experimental Background

The pressure range of the pump head is crucial for equipment performance and tube lifespan. The industry norm typically ranges between 0.05 to 0.25 MPa; too low a pressure can lead to backflow, impacting delivery efficiency, while too high a pressure can increase hose wear and shorten its lifespan.

Experimental Data

Figure: Max Pressure Values Measured by FT1505 with 13# and 25# Silicone Tubing at Different Pressure Levels

The FT1505 is capable of good compatibility with both 13# and 25# silicone tubing at both pressure levels, with stable output pressure maintained within standard range.

Data Interpretation

• Low and High Pressure Levels:

The FT1505 pump head offers low and high pressure modes, suitable for different operational requirements. The low range is suitable for scenarios with lower pressure requirements but the need to protect hose lifespan; the high range is used in applications requiring higher delivery pressure.

• Extending Tube Lifespan:

Whether for low or high flow applications, the FT1505 pump head can provide stable pressure output within the standard range. This stability not only protects the hose, extending its lifespan but also enhances the overall reliability of the equipment.

Salt Spray Experiment

(The FT1505 is undergoing salt spray testing)

Experimental Background

In actual applicatio==ns, pump heads are often exposed to humid and corrosive environments. The salt spray experiment aims to simulate a corrosive environment under harsh working conditions to verify the corrosion resistance of pump head materials, ensuring long-term stability and reliability.

Experimental Data

Following 72 hours of neutral salt spray testing, the pump head showed no abnormalities and operated normally

Data Interpretation

The FT1505 pump head is made of specialized engineering materials, demonstrating resistance to salt spray corrosion and wear, supporting prolonged high-intensity use, significantly reducing maintenance frequency and costs.

Experimental Note

This experiment strictly follows the enterprise standard Q/BLF 0111.2-2021 established by Baoding Lead Fluid Technology Co., Ltd. The data is authentic and possesses high industry reference value. However, due to possible differences in application scenarios, it is recommended to choose suitable products based on actual needs.

(Lead Fluid Laboratory)

Lead Fluid Laboratory covers nearly a thousand square meters, featuring seven professional functional areas equipped with over a hundred advanced testing devices, capable of simulating various actual working conditions. Here, not only are new products subjected to rigorous performance verification, but ongoing research on the stability and lifespan of conventional products is also conducted. Based on customer application needs, we can perform real environmental simulation tests, ensuring each experiment witnesses Lead Fluid quality, and every validation becomes a response to customer trust.

Lead Fluid always adheres to a customer-centric approach, using real data and reliable technology to validate product strength, providing trustworthy fluid transmission solutions for the industry.

For more details about the FT1505 pump head, please contact the Lead Fluid account manager. We will customize dedicated fluid control solutions for you!