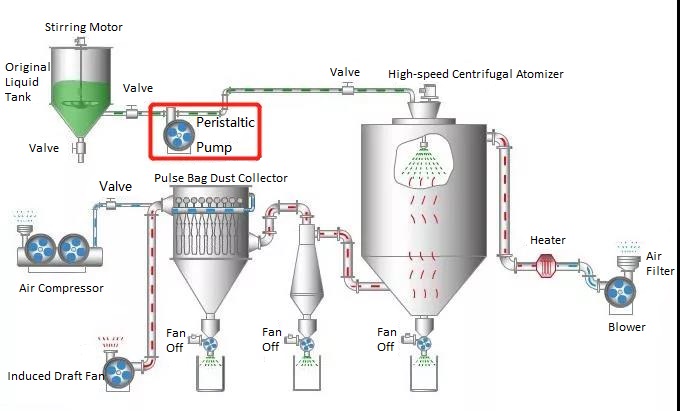

The peristaltic pump is mainly used in the spray dryer, spray dryer equipment can dry the configured raw materials into powder, granular, hollow spheres or pellets. At present, it is widely used in food, medicine and other industries.

The working principle of the spray dryer equipment is: spray the materials into droplets and disperse them in the hot air by spraying. The materials and the hot air are in contact with each other in co-current, counter-current or mixed flow, so that the moisture can be quickly evaporated to achieve the purpose of drying.

Using spray dryer equipment, compared with the dry production process, unit operations such as filtration and crushing can be omitted, the time is short, the efficiency is high, and secondary pollution can be avoided.

Which pump is used in spray dryer?

Early pain points of spray dryer equipment

In the early fluid delivery of spray dryer equipment, gear pumps or plunger pumps were mostly used, but there are many pain points in the application of these two types of pumps.

- Cleanliness requirements: The structure of gear pumps and plunger pumps is complex, which causes the liquid to remain in the pump body, which is not suitable for the high cleanliness requirements of production.

- Maintenance cost: The gears of the gear pump are easy to wear and need regular maintenance and replacement; the plunger pump has a complex structure, which requires high requirements for the conveying medium, and requires high costs for use and maintenance.

Peristaltic pumps have a variety of advantages and can perfectly replace gear pumps or plunger pumps.

- High cleanliness: the peristaltic pump transfer fluid only contacts the pump tube, not the pump body. The hoses have reached GMP, USP Class VI, FDA and NSF clean certification standards, with high cleanliness.

- Simple maintenance: The structure of the peristaltic pump is simple, without valves, seals and other components. It can be used continuously for more than 500 hours only by replacing the hose of the peristaltic pump, and the replacement of the hose can be completed in less than 1 minute. Simple and convenient, lower cost.

- Higher accuracy: The volume pumped out by the peristaltic pump is constant for each revolution, so the peristaltic pump can achieve higher accuracy and stability, and the flow rate is easy to adjust.

The peristaltic pump perfectly meets the application requirements of spray drying equipment in many aspects, and helps spray dryer equipment to work with high quality and high efficiency.

Lead Fluid peristaltic pump is used in spray dryer equipment