Fully Automated Blood Blood Slide Maker&Stainer: The “Outpost” for Microscopic Examination

When routine blood tests indicate abnormal white blood cell or platelet counts, the clinical laboratory needs to perform a blood smear microscopic examination for retesting, which is an important basis for blood disease diagnosis. However, traditional manual preparation has inherent limitations:

Time-consuming and Labor-intensive

The entire process of pipetting blood, smearing, staining, and cleaning relies on manual operations. When processing hundreds of samples per day, fatigue from operations may increase the risk of errors.

The “Trial-and-Error” of Staining

Stain solution preparation remains dependent on empirical guesswork and subjective tactile judgment. Minor miscalculations can lead to critical defects:

Proven Safety Risks

Manual handling of hazardous waste containing methanol and methylene blue exposes operators to:

Chronic inhalation risks from volatile organic compounds

Acute exposure hazards from carcinogenic reagent splashes

The Value Proposition of Automated Staining Systems

As the core fluidic component, Lead Fluid peristaltic pumps deliver two critical functions:

Precise dye transfer

• μL-level fluid control minimizes waste

• Steady flow ensures even coating

Safe waste recovery

• Fully enclosed tubing design ensures physical isolation between operators and hazardous liquids.

• Pharmed® chemical-resistant tubing compatibility meets long-term exposure requirements for reagents like methanol.

KJ15: The Precision Fluid Control Core for Dyeing Machines

Tailored for automated slide stainers, Lead Fluid’s KJ15 tackles key challenges with three core designs:

1.Precision fluid control

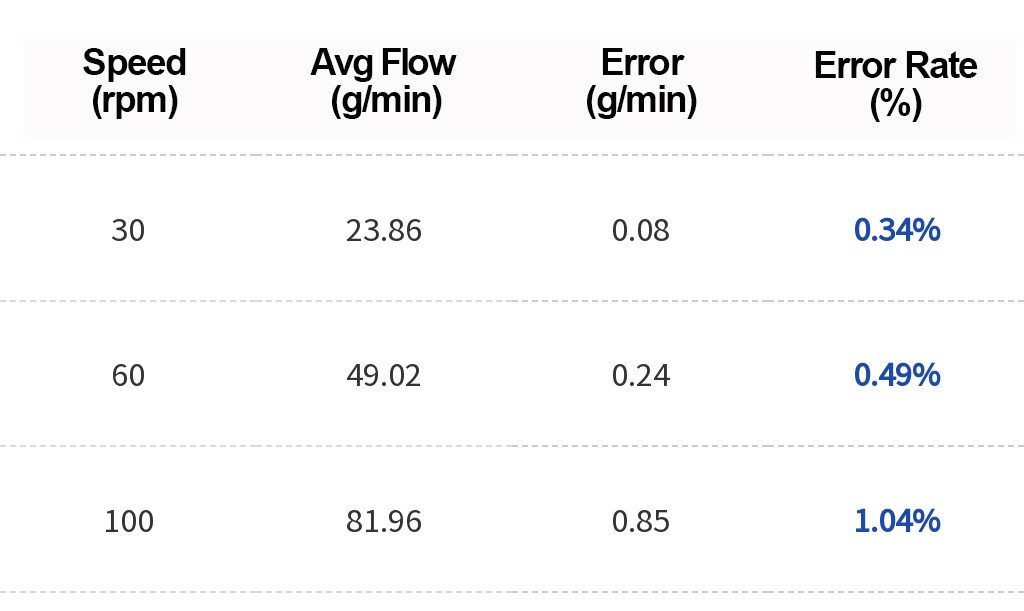

(Equipped with 25# Pharmed tubing, the system was tested with purified water by setting analog signals according to the target speed. Data is for reference only.)

• Low speed, high precision: Test data shows ≤0.5% error rate at low RPM, ensuring accurate mixing ratios for Wright’s stain and buffer to control staining consistency from the source.

• High speed, large flow rate: Rapid waste drainage minimizes equipment idle time.

2. Long-term stable operation

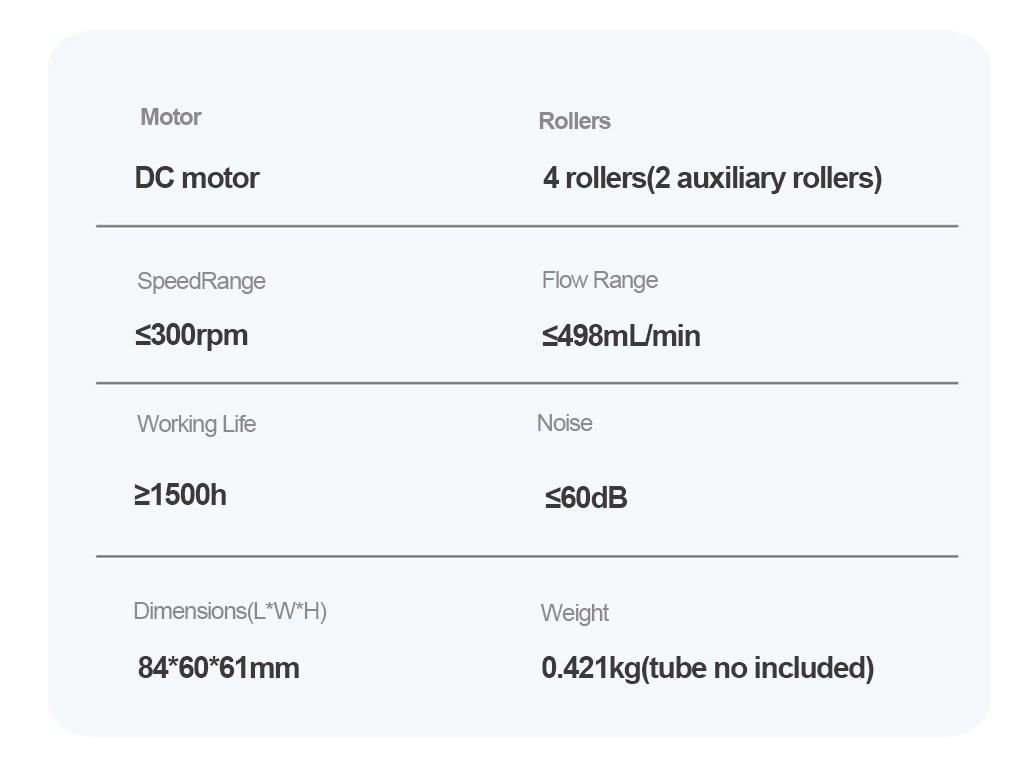

• The PPS engineering plastic pump head and PVDF roller assembly offer excellent corrosion resistance and an extended lifespan of ≥1,500 hours, significantly reducing maintenance costs.

• The PC transparent cover allows real-time operational monitoring, featuring a snap-fit design that ensures secure installation while remaining easy to detach.

3. Compact and quiet design

• Operating noise ≤60dB, suitable for laboratory environments to ensure comfortable working conditions.

• With dimensions of just 84×60×61mm (approximately palm-sized), it integrates effortlessly into equipment, enhancing both compactness and aesthetic appeal

Lead Fluid delivers more than pumps – we provide end-to-end solutions

If you are developing or upgrading automated blood smear staining equipment, Lead Fluid offers:

• Customized fluid solutions

Tailored pump head layout and tubing routing based on your equipment’s structural requirements.

• Real-world testing support

Lead Fluid Lab provides certified performance reports for stain transfer.

• 24/7 service support

24/7 consultation + 1-on-1 engineer-guided selection

Lead Fluid: Safeguarding Every Diagnosis!