How to calculate the flow rate of LeadFluid peristaltic pump

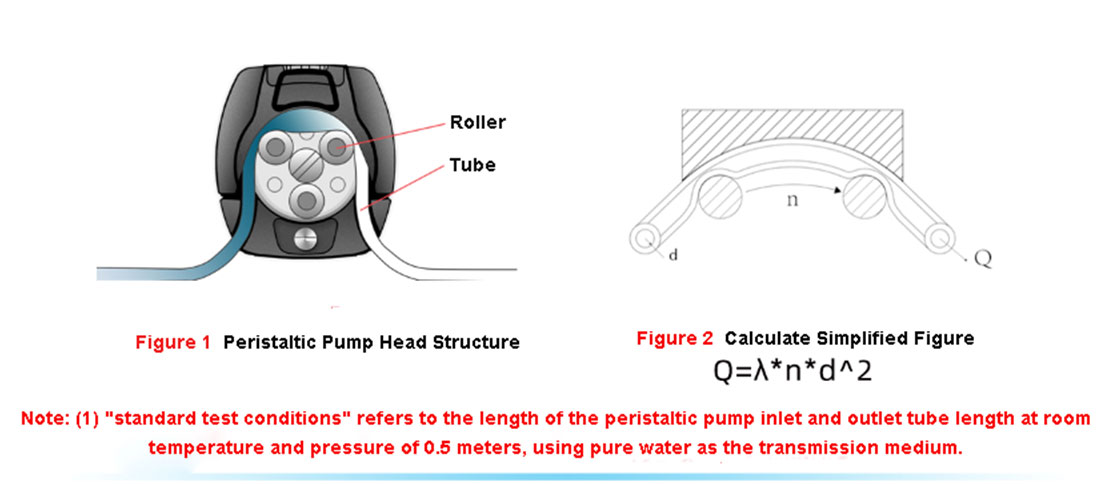

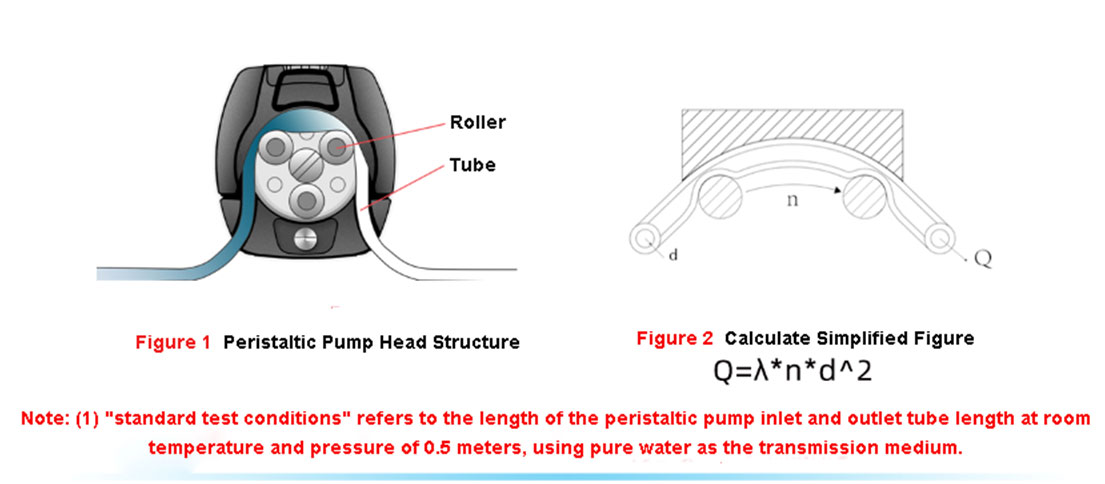

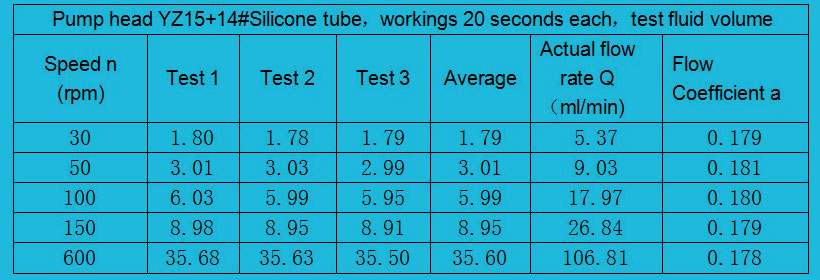

Under standard test conditions(1),the flow rate Q of the peristaltic pump is determined by the speed n of the drive, the selected tube inner diameter d and the flow coefficient λ.

Two important conclusions from the formula:

The first,The flow rate Q is proportional to the speed n. The higher the speed, the greater the flow rate.For example, when the peristaltic pump is 1rpm, the flow rate Q= 1ml/min, and it can be deduced that when the peristaltic pump is 10rpm, the flow rate Q= 10ml/min.

The second,The flow rate Q is proportional to the inner diameter of the tube d2,The change in d of inner diameter will bring a more significant change in the flow rate Q, which provides a basis for our arrangement of tube size series.

In the formula, the flow coefficientλ is mainly related to the diameter of the working circle, the number of rollers, roller diameter,tube material, flexible tube attenuationand other comprehensive factors.The larger the diameter of the working circle, the larger the flow coefficient.The number of rollers increases and the flow coefficient decreases.As the diameter of roller increases, the flow coefficient decreases.The better the flexibility of the tube, the larger the flow coefficient.A large amount of experimental data shows that in the peristaltic pump using process, the flexible tube attenuation affects the size of the flow coefficient, the flow rate of the new hose fluctuates greatly in the early stage of use,after 1-2 hours of use, the flow rate stabilizes and with the working time there is a slight attenuation.The influence of these factors is complex, and together we form a flow coefficientλ,which is constant under certain conditions.It can be measured by the method of quantitative or timing calibration of liquid volume, which is generally called the flow correction in the industry.

When customersuse LeadFluid peristaltic pump, the flow calibrate function can be used to calibrate the flow and the peristaltic pump can be set to flow mode. At this time, under the working conditions, the flow calculation model can be simplified to

Q=a*n(Equivalent formula n=Q/a,a=Q/n)

The flow coefficient is constant at different speeds. At this time, the flow rate of the peristaltic pump is proportional to the speed.The LeadFluid flow intelligent peristaltic pump is selected. The customer can set the required flow rate and the equipment automatically adjusts the speed to meet the work needs of outputting different flow rates, which is convenient to use.

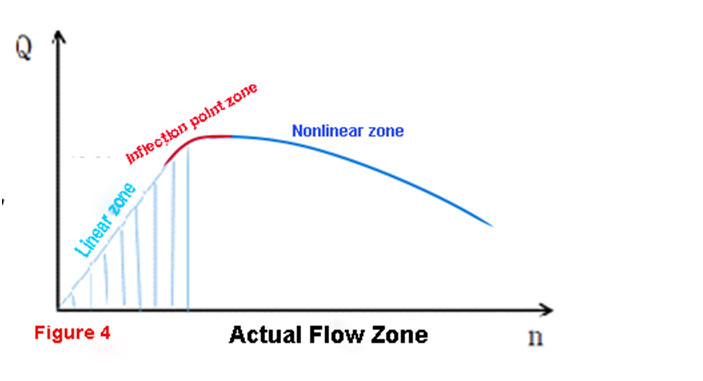

In complex actual working conditions, the relationship between flow rate and speed is shown in Figure 4.The above formula can be used to calculate flow rate Q and speed rate n only in a certain linear region. Beyond this application range, flow rate Q and speed n have a nonlinear relationship.

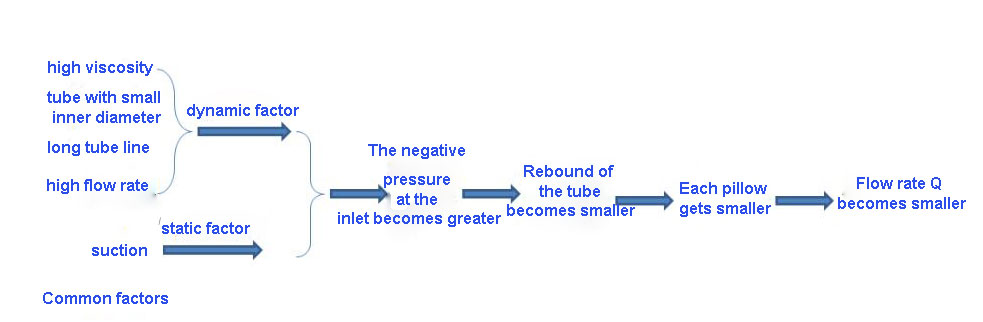

This happens in extreme situations, such as the liquid with high viscosity, the tube with smallerinnerdiameter, long tube line, and high flow rate, which will reduce the flow rate and eventually form the flow inflection point (see figure 4).After a certain speed is exceeded, the flow tends to be unchanged and no longer increases linearly with the increase of the speed, and it is easy to generateinternalatomization and vacuum inside the tube line.

The root cause of the flow inflection point is that various factors will affect the negative pressure at the inlet end of the pump head. When the degree of tube rebound increases, the non-linear change will occur and the flow will also occur non-linear changes.

LeadFluid peristaltic pump products can meet the needs of customers with different flow rates and different accuracy. More information, please contact our company’s sale managers or technicians.