Why do tablets, capsules, granules… have different drug forms?

01 meets the needs of different groups of people. If children prefer granules; For the elderly or those with difficulty swallowing, capsules or tablets are suitable.

The form of 02 drugs also directly affects the dissolution, release, and absorption of drugs, thereby affecting the therapeutic effect. For example, tablets can continuously release drugs and maintain stable blood drug concentrations; Capsules and granules have faster absorption, but they may have a certain stimulating effect on the gastrointestinal tract.

How are these different forms of drugs made?

Among them, wet granulation technology plays a crucial role. This technology forms particles of a certain size and shape by adding adhesives or wetting agents to drug powders, and through mixing, granulation, and other steps. These particles are not only the foundation of granules, but also important raw materials for capsules and tablets.

In the wet granulation process, the peristaltic pump plays an indispensable role. It is responsible for transporting liquid adhesives or wetting agents to ensure that the drug powder can uniformly and efficiently aggregate into particles. The high efficiency, uniformity, and accuracy of peristaltic pumps significantly improve the quality and consistency of drug particles, thereby ensuring the high efficiency and quality of drug production.

Customer Demand

XXX Equipment Co., Ltd. is a national high-tech enterprise that focuses on the research and development, manufacturing, sales, and service of pharmaceutical, food equipment, and information systems. To meet the high demand for fluidized bed series products in the market, we are seeking matching adhesive/wetting agent conveying equipment. The core requirements are as follows:

- High flow rate: ≥ 1000mL/min

- Strong stability: continuous and reliable, adjustable speed

- High reliability: ensuring long-term stable operation

Lead Fluid Solution

With rich project experience and professional knowledge reserves in the pharmaceutical equipment field, the Lead Fluid team quickly analyzed customer needs and accurately selected the WT300F high torque peristaltic pump as the solution for conveying fluidized bed adhesives/wetting agents.

With excellent performance and wide applicability, WT300F fully matches the three core needs of customers:

- Large flow

The WT300F peristaltic pump has excellent conveying capacity, with a flow range of 0.005~420mL/min, and supports multiple pump heads cascading, ensuring high efficiency and continuity in the production process.

- High stability

The WT300F adopts high-precision DC brushless servo drive, which has high torque, high efficiency, and maintenance free. The speed accuracy error is ≤ ± 0.2%. At the same time, it has auxiliary functions such as flow display, flow control, and liquid accumulation, making it convenient for operators to flexibly adjust the flow according to actual needs, further enhancing the controllability of the production process.

3 High reliability

The Lead Fluid WT300F has undergone strict quality control and durability testing, and can maintain stable performance under long-term continuous operation, effectively reducing failure rates and maintenance costs, providing customers with strong production support.

(Lead Fluid WT300F-4XYZ15T)

In addition, the WT300F peristaltic pump also has the following functional characteristics, which make it perform well in the production process:

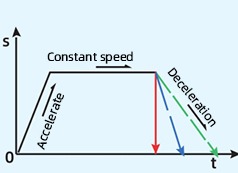

Anti-drip technology

Custom deceleration curve

Reduce liquid splashing and dripping

Clean and stable production

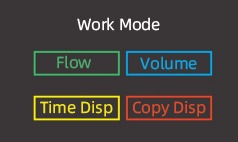

Multiple working modes

Flow rate and liquid volume

Time, Copy Allocation

Flexible and versatile

External Control Functions

RS485 communication

Compatible with MODBUS protocol

System integration and remote monitoring

Customer Feedback

A certain equipment limited company has given high praise to the application of Lead Fluid products in wet granulation machines. They stated that the WT300F peristaltic pump not only met their core needs, but also brought many unexpected surprises. They look forward to continuing to collaborate with Lead Fluid to jointly promote the development of the pharmaceutical industry.

For over a decade

Lead Fluid shoulders the mission of fluid transport

Through technological innovation

“Leading the new vitality of fluids”

Realize with perfect customized services

The pump follows the heart’s beat!