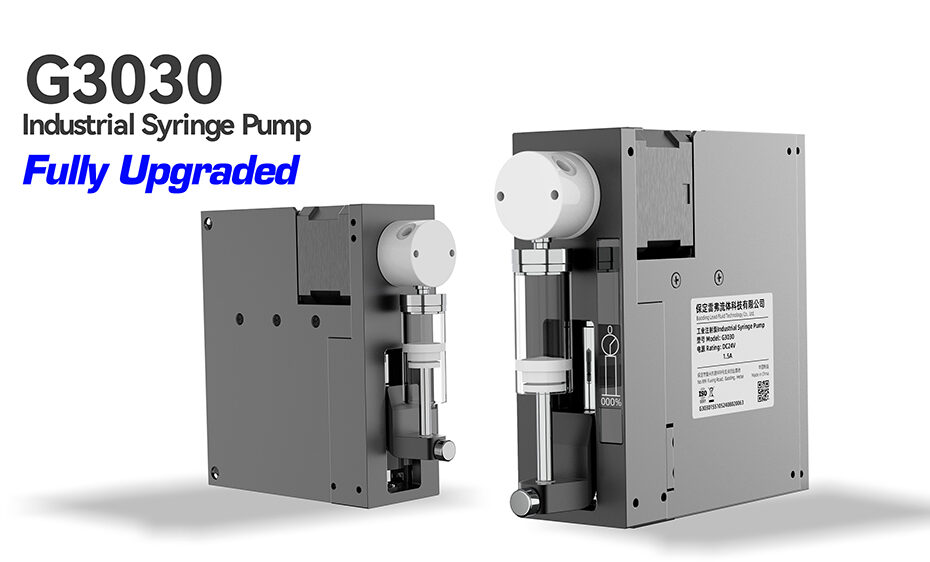

Building on the technological foundation and customer feedback from the previous two generations, the G3030 industrial micro-syringe pump has completed its third iteration upgrade, focusing on two core areas: visual interaction and the expansion of industrial protocols, providing more intuitive and reliable solutions for precise fluid control.

Upgrade Highlights

01 Industry-First OLED Display, Real-Time Monitoring

The first-generation LED status light (Patent No.: ZL 201621348864.3) has been upgraded to an OLED LCD screen, dynamically displaying the syringe piston position and valve status for more intuitive operational feedback.

Instant Overview: Power & Operational Status | Real-Time Monitoring

02 Effortless Control with CAN Bus–Your Solution for Peak Performance

Introducing CAN Bus Protocol: Ultra-fast, robust, and interference-resistant communication.

Seamless Integration with Any Device or Host System, Robust in Harsh Electromagnetic Environments, Multi-Device High-Speed Networking, and Production Line Efficiency Supercharged!

Functional Advantages

03 Cross-Compatibility

Compatible with various valve specifications and materials

Valve lifespan exceeds one million cycles

Ensures long-term reliable operation and cost reduction

04 High-Precision Feedback System

Maintains high detection sensitivity and stability in complex electromagnetic environments

Ensures high precision and consistency in fluid processing

05 Simple Installation & Efficient Maintenance

Manual pull-down for quick injector replacement

Foolproof design simplifies installation process

DIP switch facilitates easy configuration

Supports online upgrades for efficient maintenance

06 High-Performance Components

Gold-plated interfaces, durable screws, and powerful motors

Improves equipment lifespan, precision, and efficiency

Low-noise operation for comfortable user experience

07 Instruction Set Compatibility

Proprietary instruction set compatible with mainstream products

Provides broader application support

08 Flexible Configuration

Supports standalone use or 15 pumps in cascade mode

Adapts to various fluid processing requirements

09 Intelligent Limit Protection

Accurately monitors pump operating range

Prevents over-limit operations for safety assurance

Application Fields

Various fields such as environmental, industrial, and research scenarios

Typical Applications

For over a decade

Lead Fluid has taken on the mission of fluid transmission,

leading “new vitality in fluid” through technological innovation,

and realizing “pumps with user’s hearts” through perfect customization services!