Disinfection is an effective measure to cut off the transmission of infectious diseases. The occurrence of the COVID-19 has raised the importance of biosafety to an unprecedented height.

Among numerous disinfection technologies, Vaporized Hydrogen Peroxide (VHP), as an advanced high-level green disinfection technology, has significant advantages over traditional formaldehyde fumigation and chlorine dioxide gas disinfection in terms of sterilization effectiveness, personnel safety, material compatibility, and environmental friendliness. It has become one of the mainstream technologies for killing space microorganisms worldwide. So far, over 85% of the global pharmaceutical industry’s sterile isolators use VHP technology as a biological decontamination option. VHP is widely used in isolation devices, air filters, sterile filling lines, high-level biosafety laboratories, infectious disease wards, isolation stretchers, ambulances, and other fields for disinfection and treatment.

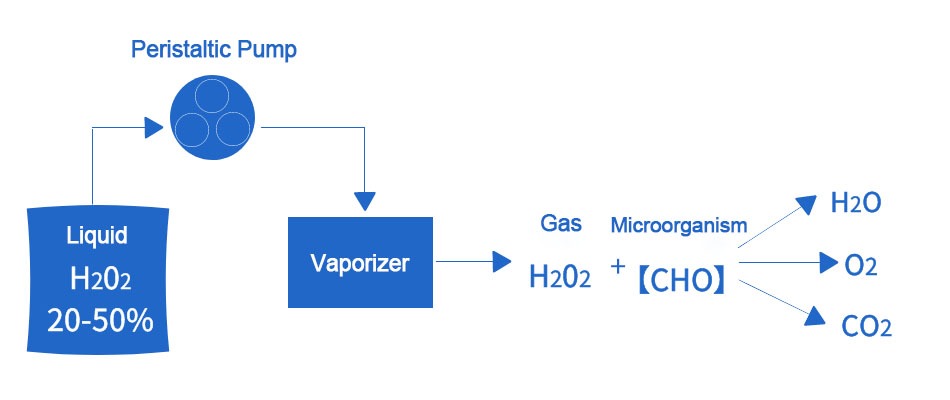

Vaporized hydrogen peroxide disinfection and sterilization technology is a technology that utilizes the advantage of hydrogen peroxide (H2O2) being more capable of killing bacterial spores in a gaseous state than in a liquid state at room temperature. By generating free hydroxyl groups, it is used to attack cellular components, including lipids, proteins, and DNA, in order to achieve complete sterilization requirements. In short, it is to transform liquid hydrogen peroxide into a vapor or dry mist gas for overall environmental disinfection.

(VHP sterilization principle)

Excessive concentration of hydrogen peroxide can easily cause corrosive effects, so uniform spraying is one of the key factors to ensure the effectiveness of VHP disinfection and sterilization. VHP typically uses a 35% concentration of hydrogen peroxide, which is instantaneously evaporated (flashed) in the generator and then dynamically sprayed into the target area. To ensure uniform distribution, the nozzle rotates horizontally and vertically at a speed of nearly 30 m/s. During this process, the peristaltic pump serves as a key power equipment for transporting hydrogen peroxide solution, ensuring the accuracy and consistency of hydrogen peroxide solution delivery in the VHP system through a stable and uniform liquid supply. It ensures the uniform distribution of hydrogen peroxide within the disinfection target, thereby achieving the expected disinfection and sterilization goals.

Customer Demand

A certain biotechnology company is an enterprise that focuses on technological innovation and product research and development in the fields of life sciences, biotechnology, analytical instruments, etc. Its products include bacterial collectors, incubators, sterile isolators, sterile transfer chambers, VHP sterilizers, and other equipment and consumables. The company has developed a hydrogen peroxide generator and is seeking a liquid supply equipment to optimize its application and meet the demand for precise and stable liquid supply.

Lead Fluid Solution

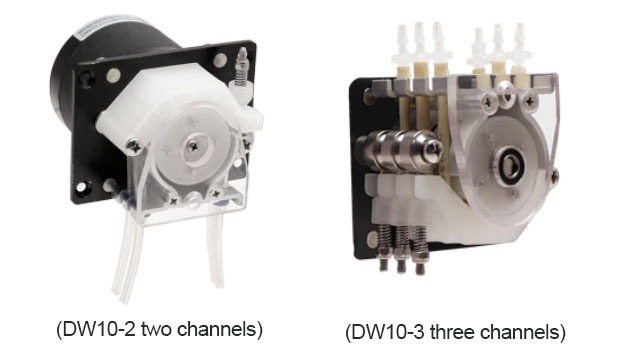

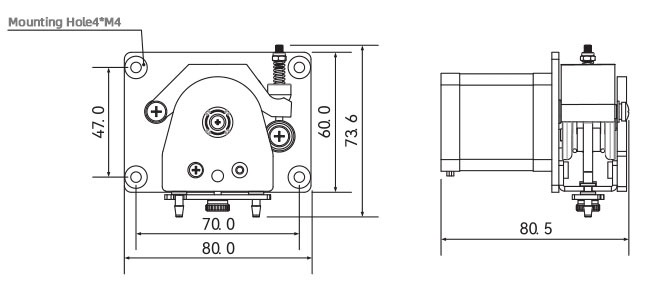

The Lead Fluid team conducted an in-depth analysis of the customer’s requirements for liquid supply equipment and provided tailored solutions, recommending the ODM product DW10 series peristaltic pump.

(Lead Fluid DW10-1 one channel)

1.Compact and beautiful, suitable for small flow supporting applications

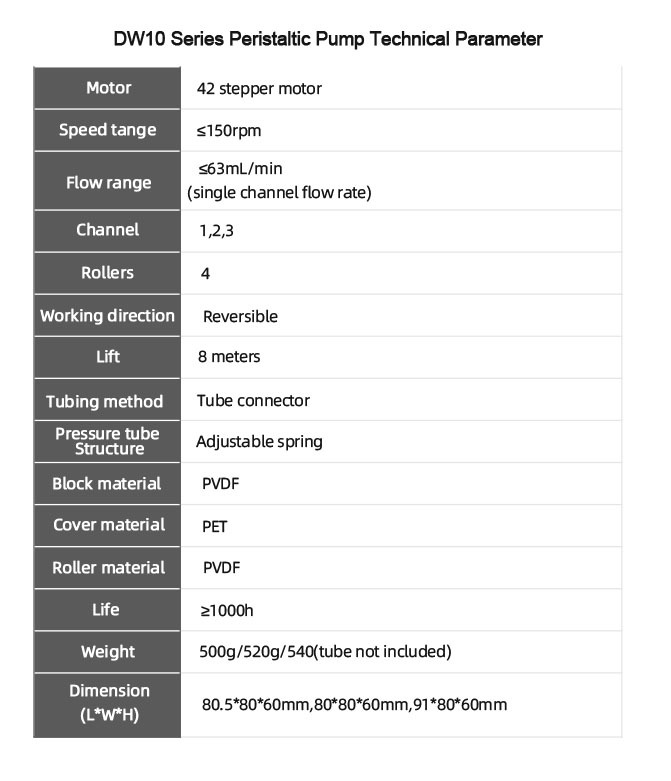

The Lead Fluid DW10 series is compact in size, aesthetically pleasing in appearance, compact in structure, with a flow range of ≤ 63mL/min, suitable for small flow applications such as VHP, and can be used in conjunction with equipment and instruments to ensure the compactness and efficiency of the overall system design.

2.High quality material selection and good corrosion resistance

The DW10 series uses hygienic and non-toxic high-quality materials with high strength, good toughness, and good chemical corrosion resistance.

3.High precision flow control

The DW10 series pump head design adopts a spring pressurized hose fixed structure, which can provide longer hose life and high-precision flow control. At the same time, by adjusting the pressure pipe device, suitable pressure can be obtained, ensuring the accuracy and consistency of hydrogen peroxide solution delivery in the VHP system.

4.Easy installation of tubes

The installation of tubes is convenient and fast, and can be adapted to various specifications of hoses to meet more application needs

5.Adjustable flow rate

The DW10 series uses analog/pulse control signals for speed regulation control, meeting the dosage requirements of VHP for different disinfection and sterilization spaces.

6.Durable

The DW10 series pump head is durable and can meet the needs of long-term operation

The Lead Fluid DW10 series peristaltic pump is compact and fixed with an embedded panel. The system adjusts the flow rate of the pump through signals, thereby adjusting the amount of hydrogen peroxide solution according to the size of the disinfection and sterilization space. While meeting disinfection requirements, it will not corrode the disinfection facilities due to excessive hydrogen peroxide gas.

Customer Feedback

The product manager of the company stated:

The Lead Fluid peristaltic pump performs excellently in supplying liquid to our hydrogen peroxide generator, providing superior performance support for our products.