Why Does the Pharmaceutical Industry Need Explosion-Proof Equipment?

In the pharmaceutical industry, flammable and explosive organic solvents (such as methanol, ethanol, and ethyl acetate) are widely used in production processes. These solvents often possess high volatility and flammability, making them prone to explosions or fires due to static electricity or sparks, particularly in enclosed or poorly ventilated environments. According to the “Good Manufacturing Practice for Pharmaceutical Products” (GMP), the design, selection, and installation of pharmaceutical production equipment must meet production standards and include explosion-proof features, especially for equipment used in flammable and explosive jobs.

Balancing explosion-proof safety with production efficiency is a core challenge for today’s pharmaceutical companies.

Three Major Challenges in Pharmaceutical Intermediates Production

Pharmaceutical intermediates are key raw materials for synthesizing drugs, and their purity and reaction conditions directly affect the quality and efficacy of active pharmaceutical ingredients (APIs). For instance, in the synthesis of anti-tumor and anti-infection drugs, intermediates require high precision in temperature, pressure, and solvent delivery to ensure reaction stability and product consistency.

However, the production process often involves strong acids, strong bases, and flammable solvents, presenting three core challenges:

01 Explosion-Proof Safety: The volatility of solvents and the potential risk of electrical sparks and static electricity make explosion-proof equipment an essential requirement for production.

02 Delivery Precision: Dosage deviations can impact chemical reactions, leading to substandard product quality.

03 Corrosion Resistance and Stability: Organic solvents impose higher durability requirements on equipment materials, necessitating long-term stable operation.

As safety and quality demands in the pharmaceutical industry continue to tighten, the choice of compliant and efficient explosion-proof equipment has become an imperative for companies.

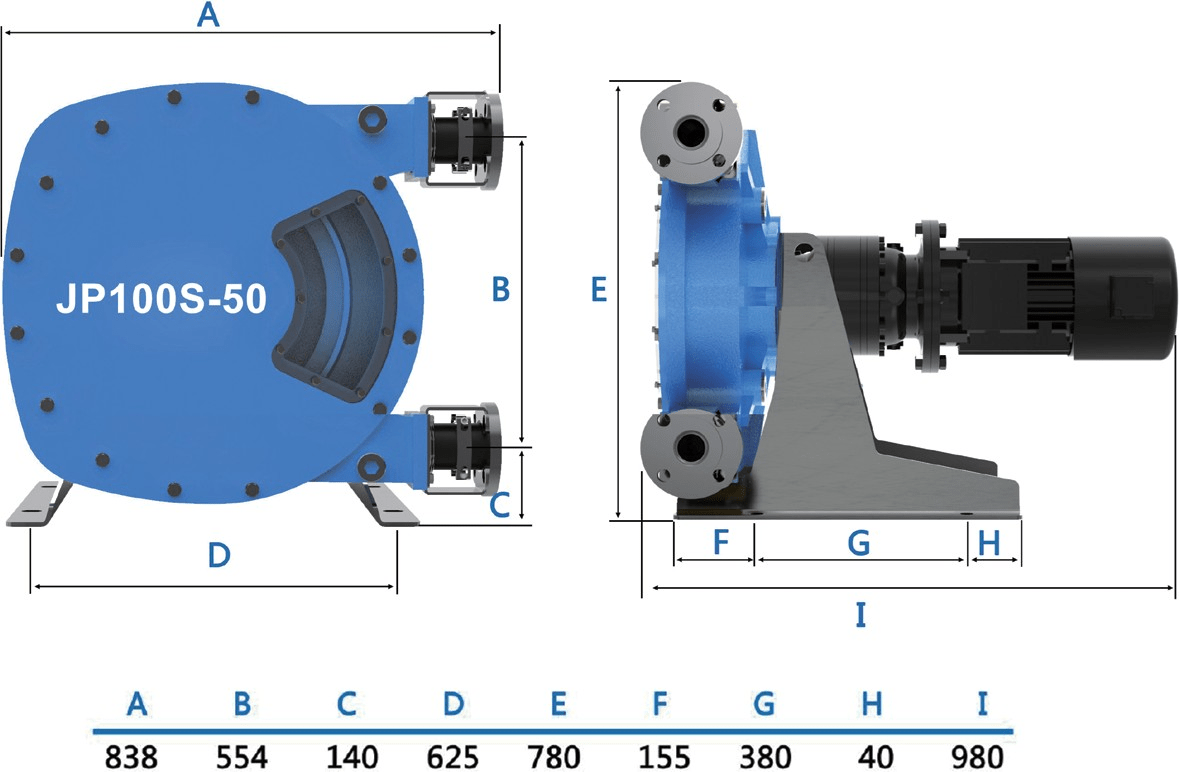

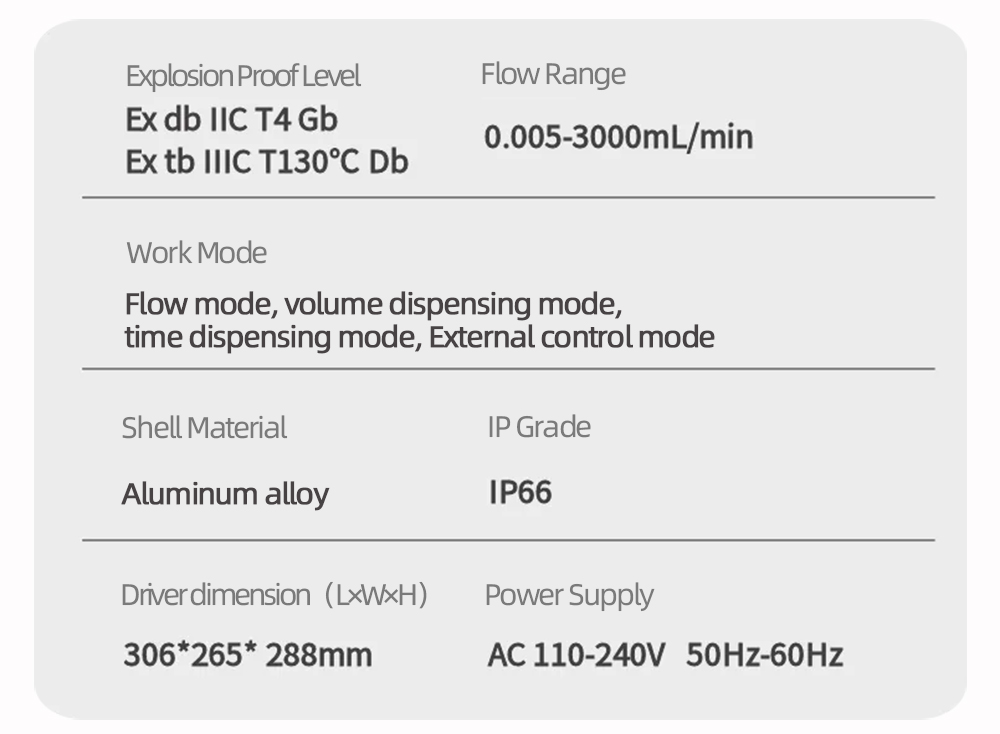

Lead Fluid Solution: EF903 Explosion-Proof Peristaltic Pump

In response to the challenges faced by pharmaceutical companies, the Lead Fluid EF903 explosion-proof peristaltic pump offers exemplary performance and innovative design, providing safe and efficient transportation solutions for pharmaceutical enterprises.

- Explosion-Proof Performance:

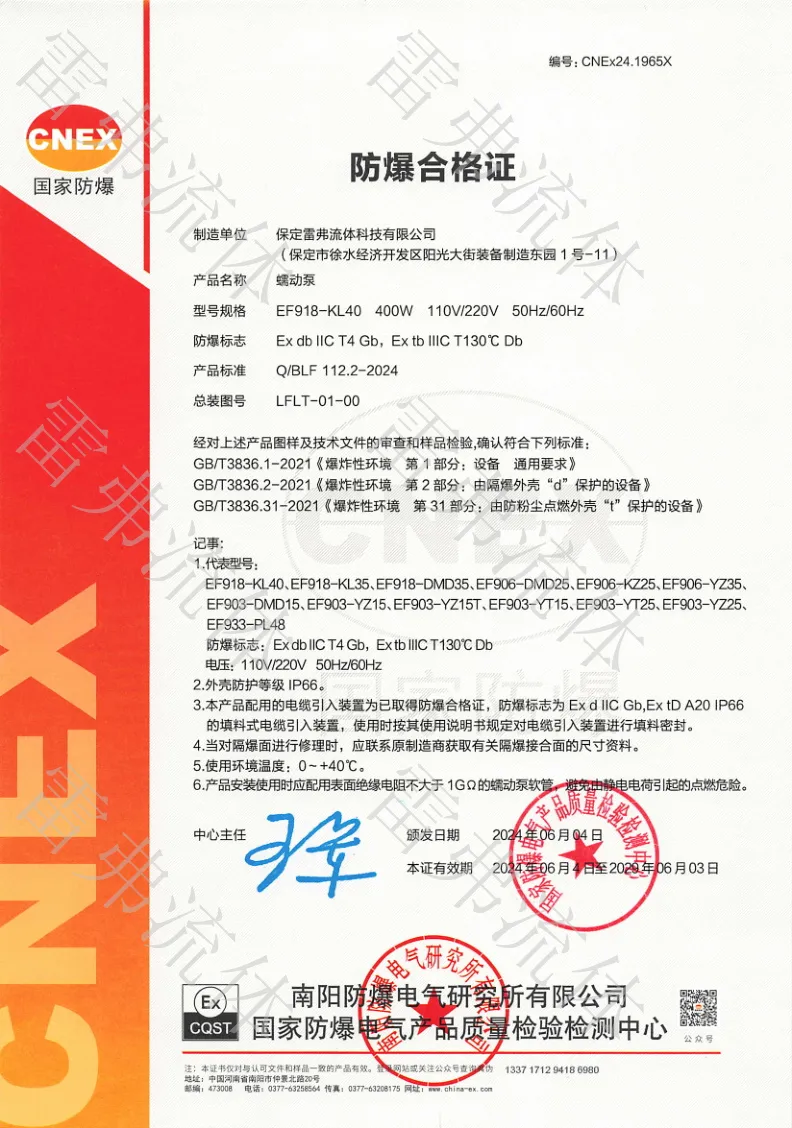

With national explosion-proof certification and dual protection against dust explosion and flame-proofing, the EF903 is suitable for Class II C explosive gases (zones 1 and 2) and Class III C explosive dusts (zones 21 and 22), effectively preventing explosion risks and ensuring production safety.

- Precise Fluid Control:

The powerful 400W motor ensures speed accuracy within ±0.2%, achieving precise delivery while supporting a cascade of 10 YZ15T pump heads, allowing for bulk delivery with a single machine, thereby enhancing production efficiency.

- High Pressure and Corrosion Resistance:

The integrated aluminum housing is easy to clean and effectively prevents corrosion from various acids, bases, salts, and organic solvents, withstanding high pressure (2.0 MPa) and suitable for complex working conditions.

- Cost Savings:

With patented calibration algorithms, the pump saves three times the original solution and improves efficiency threefold, effectively controlling production costs.

- High Protection Rating (IP66):

Dustproof and waterproof, the pump can operate stably in harsh environments with dust, moisture, and weak acid/alkaline mist, reducing downtime and maintenance frequency.

- Intelligent and Convenient Operation:

- Quick parameter settings, efficient displacement adjustments, reducing operation time.

- 5-inch wide-view LCD screen, clearly visible from various angles.

- Three-level permission management to meet pharmaceutical companies’ compliance requirements.

- Supports network communications without rewiring, allowing for flexible switching of analog types.

EF903 Application Practice

The EF903 has been stably operated in key processes such as solvent transportation and precise raw material addition in multiple pharmaceutical enterprises, demonstrating excellent performance in safety and precise flow control. Not only has it helped companies achieve safe production, but it has also improved overall production efficiency and product qualification rates.

In the future, Lead Fluid will continue to uphold the spirit of innovation, focus on customer needs, and continuously launch more high-performance fluid control products to contribute to the development of the pharmaceutical industry.

For over a decade

Lead Fluid has taken on the mission of fluid transmission,

leading “new vitality in fluid” through technological innovation,

and realizing “pumps with user’s hearts” through perfect customization services!