Filling Is More Than Dispensing—It’s Key to Production Stability

In the pharmaceutical production process chain, filling is a critical step that precisely distributes liquid medication into containers according to set dosages. Its accuracy, stability, and cleanliness not only ensure compliant product delivery but also directly impact the efficiency of the entire production line.

A single dosage deviation can lead to batch scrapping, while even a few minutes of unplanned downtime can affect overall production capacity. Additionally, minor contamination risks during filling may result in quality hazards or even recalls. Achieving precise filling, stable operation, and sterile assurance has become a core focus for pharmaceutical companies in equipment selection and production line design.

01 Why Choose a Peristaltic Pump?

Compared to traditional filling equipment like piston pumps or gear pumps, peristaltic pumps are an ideal choice for pharmaceutical filling due to their gentle transfer, contamination-free contact, and low-pulse control:

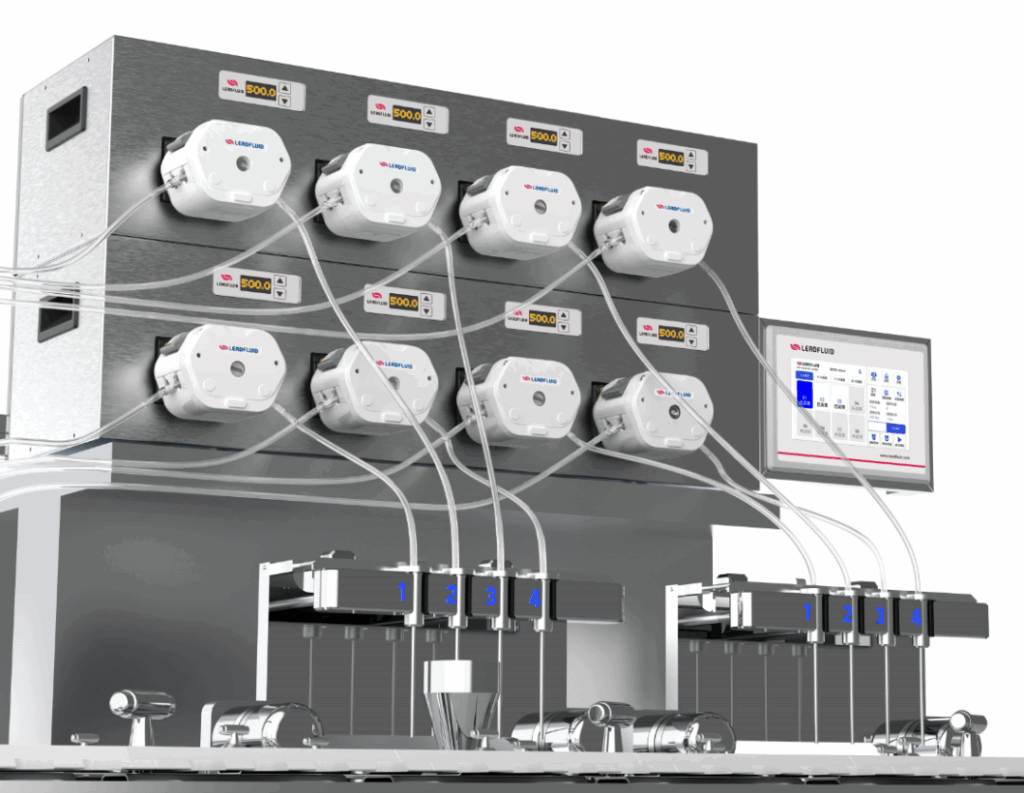

02 DMD15: Precision Filling Solution

A domestic pharmaceutical company has newly established three production lines covering various dosage forms, including oral solutions and injectables, facing two main challenges: insufficient precision in micro-filling and poor stability in continuous production. The Lead Fluid DMD15 addresses these challenges through the following technological innovations:

High Precision, Low Pulse

Utilizes roller phase compensation technology to reduce pulse, ensuring filling precision within 200μL ±3μL for reliable micro-filling.

Multi-Spec Compatibility, Stable Transfer

Equipped with elastic pressure blocks to flexibly adapt to various tubing sizes, reducing leakage risks and extending tube lifespan. Minimizes tube replacement frequency, enhancing production continuity.

Easy Tubing Installation, Low Maintenance

Dedicated tube design with auto-centering eliminates tedious adjustments, reducing downtime.

User-Friendly Operation, Improved Efficiency

Non-slip dual-ear lever allows one-handed operation, reducing operator strain and adapting to high-paced production environments.

Safety Design for Peace of Mind

Supports automatic shutdown when the cover is opened, ensuring operational safety.

Performance-Driven, Enabling “Stable, Precise, and Fast” Production

The Lead Fluid DMD15, with its precision mechanical design and deep adaptation to pharmaceutical scenarios, offers a cost-effective filling solution for pharmaceutical companies.

Lead Fluid Provides End-to-End Solutions04

✅ Customized Fluid Solutions

Tailored pump and tubing combinations based on drug characteristics and dosage requirements.

✅ Real-World Testing Support

Validated flow rates, pulse, and filling precision with data-driven assurance.

✅ 24/7 Service Support

Round-the-clock consultation and one-on-one engineer guidance for equipment selection.

Lead Fluid Technology delivers precise, controllable, and cost-efficient fluid transfer solutions for pharmaceutical filling.