Intelligent touch screen precision peristaltic pumps have become the preferred choice for most biologics filling processes. Because automating production processes can provide the advantages of more robust production and greater flexibility. Therefore, in aseptic filling operations, most biologics are produced by microbial fermentation or mammalian cell culture. Microbial contamination affects the robustness and reproducibility of biomanufacturing processes, as well as the purity, efficacy, and safety of the final drug product.

While the biopharmaceutical industry is developing rapidly, requiring effective contamination control in the production process to reduce the risk of non-compliance and reduce downtime. With the increasingly fierce competition in the drug market and the increasingly strict supervision of the drug safety market, many biopharmaceutical companies have an increasingly urgent need for intelligent, automated and digital process production. Compared with the traditional production mode.

Lead Fluid peristaltic pump has a wide and adjustable flow range, excellent liquid filling accuracy and stability, high degree of automation, reduced human interference in parts replacement and maintenance, and low shear force characteristics can greatly protect biological products from being damaged. Destruction, especially for biological product processes.

Application of Lead Fluid BT300F intelligent high-precision peristaltic pump in aseptic filling industry

The filling equipment developed by a pharmaceutical equipment design company uses the Lead Fluid BT300F intelligent peristaltic pump. By configuring the intelligent pump, it can achieve high repeatability and precise delivery of liquid medicines, improve filling efficiency, and reduce manual operations and waiting time. At the same time, the gentle pumping action eliminates foaming, splashing or dripping, preventing costly overfilling and helping to optimize final product quality and cost.

The customer said: Aseptic filling is a key process in biopharmaceuticals, we hope that the developed equipment can meet the customer’s requirements. And it is our challenge to provide a filling equipment that can meet a variety of high-precision filling volumes. Lead Fluid precision peristaltic pumps provide accurate and repeatable flow and have become an essential part of our equipment.

BT300F Dispensing Peristaltic Pump Function

BT300F suitable for pump head

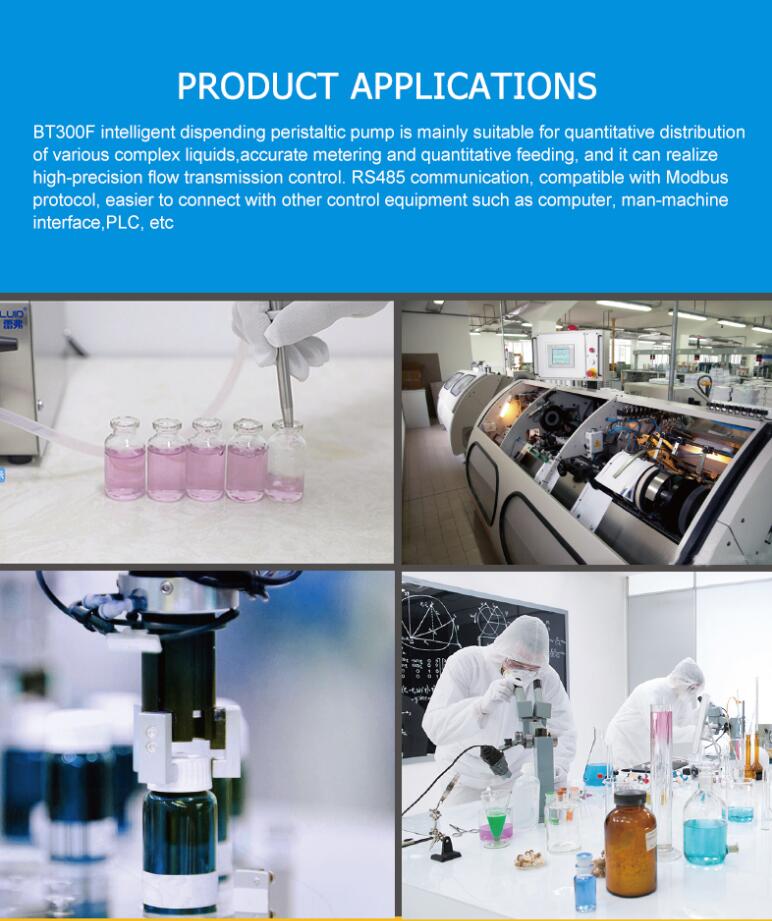

BT300F precision peristaltic pump application