As precision fluid transfer devices, the type of drive motor in peristaltic pumps directly affects their performance and application scenarios. Based on motor types, peristaltic pumps can be primarily categorized into four main classes, each with distinct technical features and suitable applications.

-

Stepper Motor-Driven Peristaltic Pumps

Stepper motor-driven peristaltic pumps hold significant importance in precision control applications. These pumps utilize pulse signal control, capable of dividing each rotation into hundreds or thousands of microsteps, achieving extremely high angular resolution. Their most notable feature is excellent low-speed stability, maintaining flow accuracy of ±0.5% within the 5-100rpm speed range, making them particularly suitable for precise micro-volume liquid transfer. Laboratory microinjection pumps typically employ this design, enabling stable delivery at rates of several milliliters per hour. However, as stepper motors may experience step loss at high speeds, their accuracy significantly decreases when exceeding 300rpm, making them unsuitable for high-flow applications. -

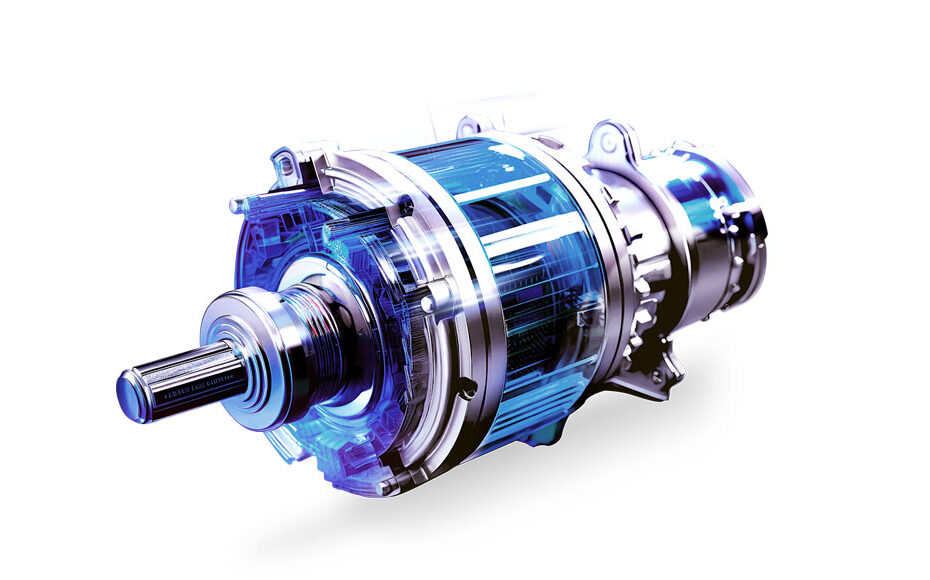

Servo Motor-Driven Peristaltic Pumps

Servo motor-driven peristaltic pumps represent the high-end application direction. These pumps incorporate closed-loop control systems with encoder feedback providing real-time position information, achieving positioning accuracy up to ±0.1°. Their greatest advantage lies in fast dynamic response, with acceleration reaching 3000rpm/s, perfectly matching processes requiring quick start-stop or variable speed operation. In automated production lines, servo-type peristaltic pumps can precisely synchronize with other equipment. Additionally, servo motors maintain stable torque output across a wide speed range (10-600rpm), making them suitable for both micro-dosing and medium-flow applications. However, higher manufacturing costs limit their use in ordinary applications. -

DC Motor-Driven Peristaltic Pumps

DC motor-driven peristaltic pumps offer the most economical and practical solution. Utilizing brushed or brushless DC motors with PWM speed control achieving a 1:100 speed ratio, these pumps feature simple structure, easy maintenance, and compact size, making them widely used in portable equipment. Typical applications include agricultural irrigation and mobile water treatment systems. Although their control accuracy is relatively lower (approximately ±3%), it sufficiently meets basic requirements for most industrial scenarios. The brushless DC motor version can exceed 10,000 hours of service life, especially suitable for continuous operation applications. -

AC Motor-Driven Peristaltic Pumps

AC motor-driven peristaltic pumps are designed specifically for high-flow industrial applications. Using three-phase induction motors with power ratings typically between 0.5-5kW, they provide stable high-torque output. These pumps are most characterized by exceptional durability, capable of 24-hour continuous operation with long maintenance intervals. Widely used in chemical and water treatment industries for large-scale dosing systems, single-pump flow rates can exceed 100L/min. Although their speed regulation performance is relatively limited, frequency converters still enable 30-100% flow adjustment range. Their rugged design makes them particularly suitable for harsh industrial environments.

Continuous progress in motor technology drives peristaltic pumps toward greater precision and intelligence, providing more specialized fluid handling solutions across industries. When selecting pumps, users should consider actual application requirements including flow range, accuracy needs, and budget constraints to choose the most suitable drive type.