Laboratory achievements embark on the path of production line

Industrial scaling up is the process of expanding the successfully validated technology or process scale in the laboratory to industrial production. This process is not a simple scale expansion, but involves complex transformation of technology and process, involving scaling up from laboratory bottles and cans to a scale of tens of tons. This process faces many challenges, among which the efficiency and feasibility of the separation process become the key factors determining the success of industrial scale production. Separation refers to the engineering operation of effectively separating different components in a mixture using distillation, extraction, crystallization, filtration, and other methods based on the differences in the characteristics of different substances.

In the petroleum, chemical, and biochemical industries, the separation process usually accounts for 50% to 90% of infrastructure investment. Therefore, improving separation efficiency, reducing energy consumption, and innovating technology will greatly empower the high-quality development of the chemical industry. It is an important way for the chemical industry to enhance its core competitiveness and solve some of the bottleneck problems faced by China.

Relying on the team of the Key Laboratory of Green Process and Engineering of the Chinese Academy of Sciences established by the Process Engineering Research Institute of the Chinese Academy of Sciences, the gas assisted superparamagnetic separation process equipment was innovatively developed, and the magnetic particles were really used as the extractant to realize the continuous operation of multi-stage extraction and stripping, so as to realize the large-scale continuous separation of the target product and solve the problem of industrial amplification.

Gas assisted superparamagnetic separation process equipment

The Key Laboratory of Green Process and Engineering of the Chinese Academy of Sciences is committed to the application foundation and engineering research of green chemistry and process, green reaction engineering, green separation engineering and green process system integration.

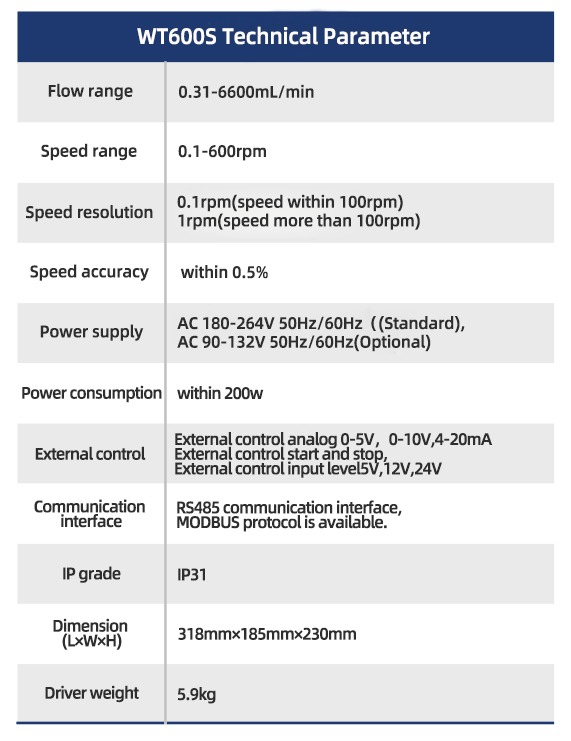

The air assisted superparamagnetic separation equipment is a complex system that requires extremely high separation efficiency and equipment stability. The Ralph WT600S high torque speed regulating peristaltic pump plays a crucial role in this system, ensuring the smooth progress of separation engineering through its efficient pumping capacity, and providing strong support for achieving efficient, economical, and environmentally friendly industrial scaling.

Lead Fluid WT600S large torque speed variable peristaltic pump

• LF-LCD-OS Software System, High Definition LCD screen, Chinese and English switching, simple parameter setting, intuitive status display.

• High quality large torque brushless servo motor drive, precise speed, wide range, stable operation, can achieve high precision flow transmission.

• Industrial-grade membrane key operation, simple and convenient, strong durability.

• LF-EasyChange universal design, high torque output, can be installed with multiple KZ25 pump heads, KZ25-L pump heads and GN10 pump heads.

• Start/stop, reversible direction, full speed, adjust speed, state memory (power-down-memory).

• Parameters setting such as running time, interval time, and number of cycles to meet the needs of timing, liquid packaging, flow testing, etc.

Lead Fluid KZ25 series peristaltic pump

■ Lead Fluid KZ25 pump head flow range 0.31~6600mL/min, suitable for 15#, 24#, 35#,36# tube, can be cascade multiple pump heads.

■ Easy, fast load and replace tubes.

■ The rollers adopts 304SS, excellent mechanical properties, can work continuously at high speed for a long time.

■ The shell adopts kinds of material, suitable for various working environment.

PC (Polycarbonate) – The outer shell is made of transparent PC material with moderate strength, making it easy to observe the internal working condition of the pump head; The upper pressure block adopts PPS, which has high strength, good chemical stability, and high temperature resistance

PPS (polyphenylene sulfide) – The shell and upper pressure block are made of PPS material, which has strong corrosion resistance and stronger adaptability

AL (aluminum alloy) – a precision processed all aluminum alloy material with high precision, suitable for hoses with high hardness, and strong weather resistance

The scientific research achievements of the laboratory have been successfully scaled up through industrial production, bringing revolutionary changes to the industry. In this process, the Lead Fluid peristaltic pump played an important role as a key equipment, and its application in the gas-assisted superparamagnetic separation process equipment laid a solid foundation for this innovation. Provided strong support for future technological innovation and industrial development in the industry.