The laboratory syringe pump is one of the commonly used transfer pumps. Today, let’s see what magic power it can exert in various fields?

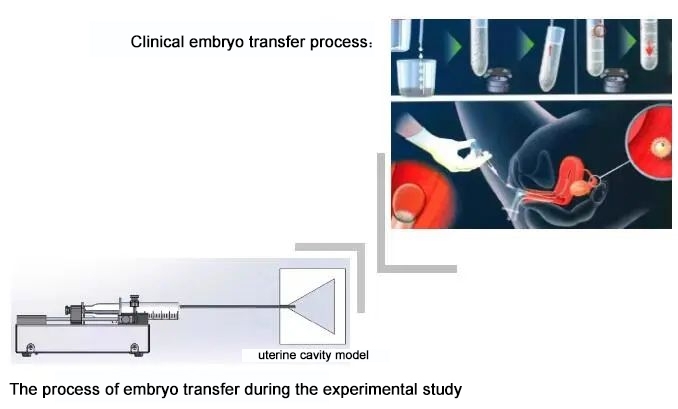

1.InVitro Fertilization-Embryo Transfer

In vitro fertilization embryo transfer (IVF-ET) technology refers to the technology that eggs and sperm are taken out, placed in test tubes or petri dishes to fertilize them, and then transferred back to the mother’s womb to develop into a fetus. It is one of the treatment measures for infertility.

In order to further improve the success rate of IVF, medical laboratories at home and abroad have carried out a lot of experimental studies on the process of IVF embryo transfer. In order to ensure the stability and reliability of the experimental data, the injection pump was used to simulate the manual embryo injection process of medical staff in the clinical process.

The syringe pump in the laboratory of Lead Fluid has exquisite structure, high precision and stable operation, which is easy to use with other instruments and equipment in the laboratory. When the embryo is injected, the flow is stable and uniform with low pulsation, which can effectively reduce the pressure fluctuation in the uterine cavity during embryo transfer, and ensure that the pressure in the uterine cavity during the injection process is within the acceptable range of the human body.

The syringe pump in the laboratory of Lead Fluid has exquisite structure, high precision and stable operation, which is easy to use with other instruments and equipment in the laboratory. When the embryo is injected, the flow is stable and uniform with low pulsation, which can effectively reduce the pressure fluctuation in the uterine cavity during embryo transfer, and ensure that the pressure in the uterine cavity during the injection process is within the acceptable range of the human body.

2.Electrospinning

High voltage electrospinning is a special fiber manufacturing process, in which polymer solution or melt is jet spun in a strong electric field. The fibers made by electrospinning are more slender than those made by traditional spinning, and their diameters are generally tens to thousands of nanometers.

High voltage electrospinning requires that the spinning solution is transported through the injection pump, and the droplets are extruded from the spinneret to form droplets. The droplets become tapered under the action of high voltage, and are further excited to form jets after exceeding a certain critical voltage. The jets vibrate and whip sharply in the air, so as to stretch and refine, and finally settle on the receiving device to form nonwoven nanofibers.

High voltage electrospinning requires that the spinning solution is transported through the injection pump, and the droplets are extruded from the spinneret to form droplets. The droplets become tapered under the action of high voltage, and are further excited to form jets after exceeding a certain critical voltage. The jets vibrate and whip sharply in the air, so as to stretch and refine, and finally settle on the receiving device to form nonwoven nanofibers.

The syringe pump of the Lead Fluid laboratory has accurate and correctable flow, which can make the flow more match with the action of the voltage and spinning receiver, help to form a stable Taylor cone, and reduce the fiber diameter. Moreover, it has strong anti electromagnetic interference performance, can continuously and stably operate under high voltage electrostatic field, and helps to improve spinning efficiency.

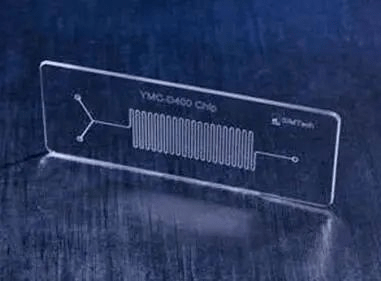

3.Microfluidic chip

Microfluidic chip, also known as chip laboratory, is a kind of science and technology characterized by the manipulation of fluids in the micro nano scale space. It can reduce the basic functions of biological, chemical and other laboratories, such as sample preparation, reaction, separation and detection, to a few square centimeters chip, which can be widely used in medicine, biology, chemistry, physics and other fields.

The main feature of the microfluidic chip system is the microchannel network of various configurations. The analysis function of the chip system is completed by controlling the microfluidics in the channel. Microfluidic driving system is the premise and foundation of microfluidic control. At present, the fluid drive system used in the microfluidic analysis system is mainly the syringe pump.

The main feature of the microfluidic chip system is the microchannel network of various configurations. The analysis function of the chip system is completed by controlling the microfluidics in the channel. Microfluidic driving system is the premise and foundation of microfluidic control. At present, the fluid drive system used in the microfluidic analysis system is mainly the syringe pump.

The syringe pump in the laboratory of Lead Fluid has the advantages of stable driving flow and wide adjustable range. The average flow in the device will not change due to the actual change of the device flow resistance, which can deeply fit the application of microfluidic chip system.

Syringe pump has so many applications. If you are interested in it, welcome to connect Lead Fluid company.