•Lead Fluid DG series pump head designed for small flow and multi-channel fluid transmission, it can realize simultaneous transmission of more than 1-48 pipelines with compact structure and convenient use.

•Exquisite structure design, even compared with traditional multi-roller pump head, can still provide very low transmission pulsation.

•Reasonable mechanical structure and high precision processing technology ensure the consistency of flow between channels.

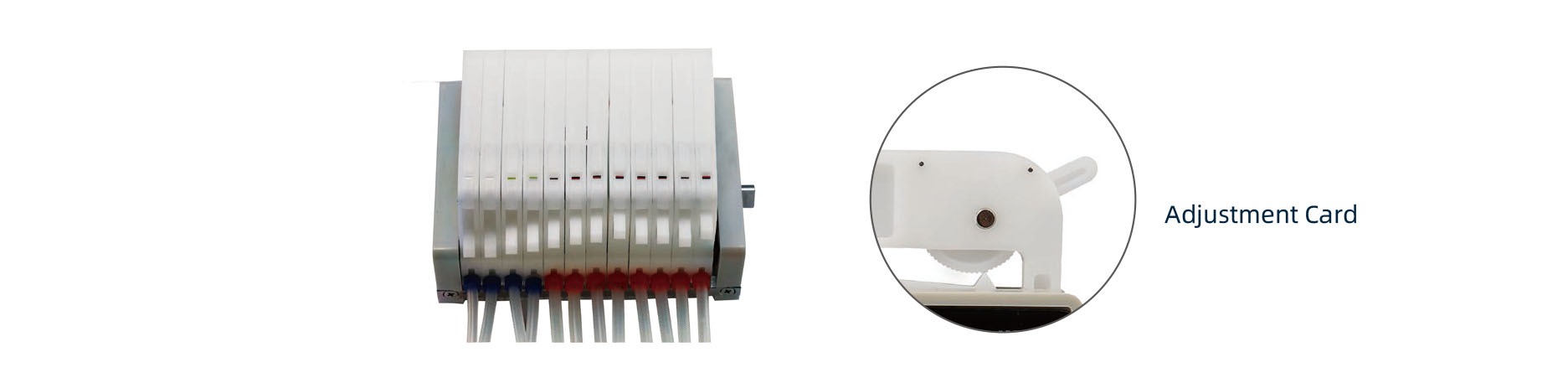

•The card-type structure can be loaded and unloaded independently, which is easy to replace and fix the pump tube .

•There are two kinds of card pressure tube device ratchet adjusting device and adaptive spring device, adjustment card with shift display, pressure tube clearance can be based on manual adjustment according to the size of tube, to adapt to different wall thickness of tube and transmission pressure. Self-adaptive design of spring card , pressure tube clearance will be adjusted automatically according to the thickness of tube.

•High strength stainless steel is used as the material of pump head roller, and POM and PVDF high function plastics are selected as the card material to meet the requirements of different working conditions.

•Can suitable for tube of wall thickness 0.8~1mm, ID 0.13~3.17mm Silicone, Pharmed, PVC, Viton and other materials and specifications, single channel flow range is 0.0001~49ml/min.

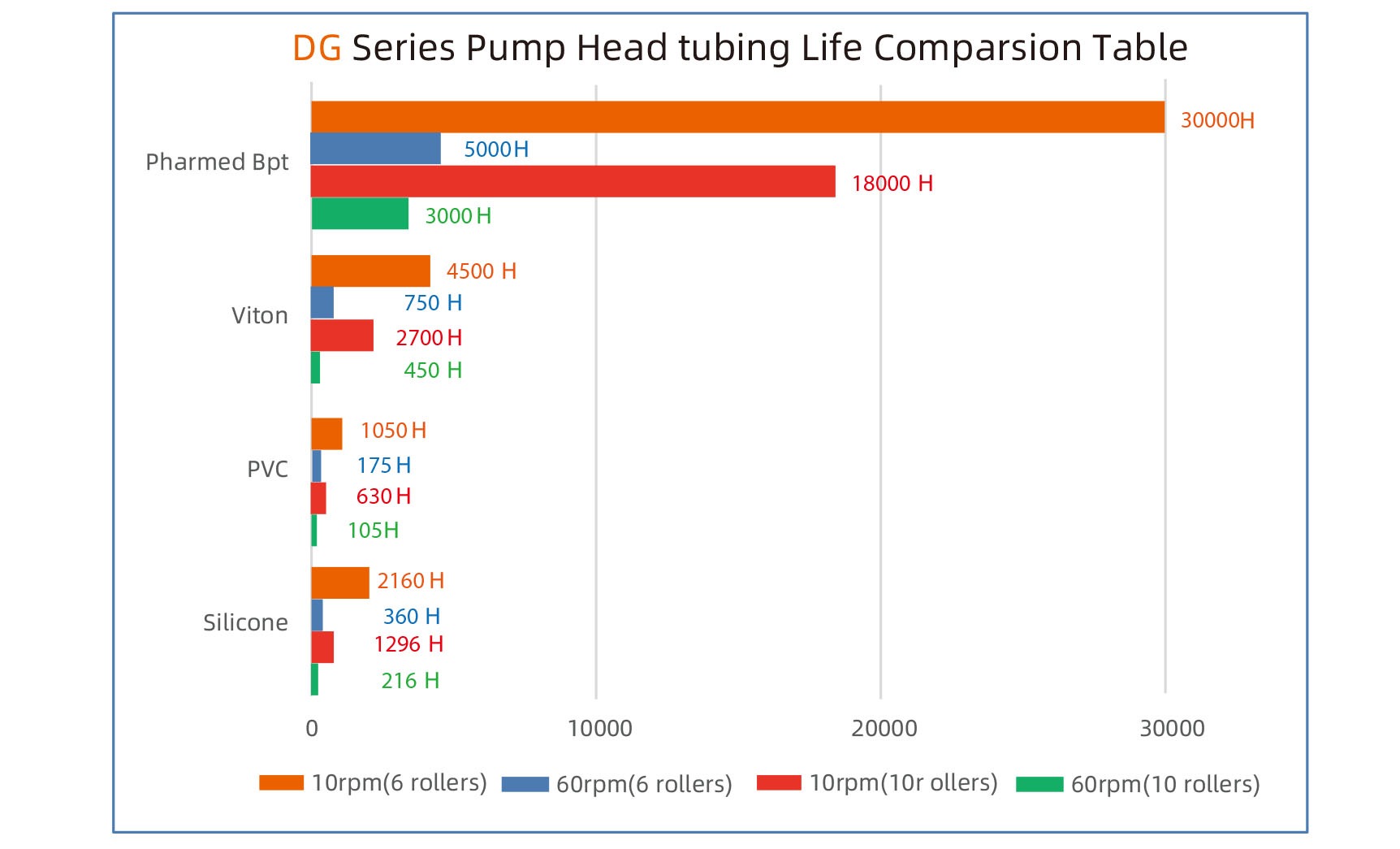

•Number of pump head roller 6 or 10 optional, 6 rollers pump head with wide flow range, long tube lifetime, 10 rollers pump head with less transmission pulsation and tube wear higher.

•Can match speed below 100rpm stepper motor, servo motor, AC gear motor, DC gear motor and other motors.

Pump Head Material

- Roller: SS 304/SS 316

- Card: POM /PVDF

Flow Parameters

Tube material:Silicone,Pharmed,PVC,Viton,etc. Wall thickness 0.86~1mm

| ID(mm) | 0.13 | 0.25 | 1 | 1.52 | 2 | 2.4 | 3.17 |

| (DG6 rollers) | |||||||

| mL/rpm | 0.0016 | 0.006 | 0.064 | 0.15 | 0.24 | 0.31 | 0.49 |

| mL/min( continuous working max 100rpm) | 0.16 | 0.6 | 6.4 | 15 | 24 | 31 | 49 |

| (DG10 rollers) | |||||||

| mL/rpm | 0.0011 | 0.0039 | 0.049 | 0.11 | 0.18 | 0.21 | 0.32 |

| mL/min( continuous working max 100rpm) | 0.11 | 0.39 | 4.9 | 11 | 18 | 21 | 32 |

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure,in actually using it is effected by specific factors such as pressure, medium etc. Above for reference only.

Tube with inner diameters of 3mm and above are subject to wear and tear, which affects their service life.

DG Series Pump Head

Adjustment Cartridge pressure tube clearance can be adjusted by ratchet structure , there are 7 adjusting gears with color marks corresponding to tube of different specifications and materials, can work under the optimum pressure tube clearance without user debugging, obviously prolonged the tube lifetime, if need larger outlet pressure,the pressure tube clearancecan be reduced by adjusting the gear, and the operation is simple.

Adjustment Cartridge Automatic adjustment of pressure tube clearance through high performance alloy spring , in order to adapt to the wall thickness change of tube due to long-term use,the uniform stability of flow can be effectively guaranteed.

Adjustment Cartridge Automatic adjustment of pressure tube clearance through high performance alloy spring , in order to adapt to the wall thickness change of tube due to long-term use,the uniform stability of flow can be effectively guaranteed.

Pump Head Specification

- Channel: 1/2/4/6/8/12(one pump head,max expand to 48 channels)

- Roller: 6/10 rollers

- Speed range: 0.1 ~100rpm/min

- Flow range: 0.00011 ~ 49mL/min

- Tube: Wall thickness: 0.8mm~1mm, ID:0.13mm~3.17mm

- Pressure Tube Clearance: Automatic/manual adjustment

- Working environment: Temperature 0 ~ 40℃, relative humidity<80%

- Motor: stepper motor, servo motor, AC gear motor, DC gear motor

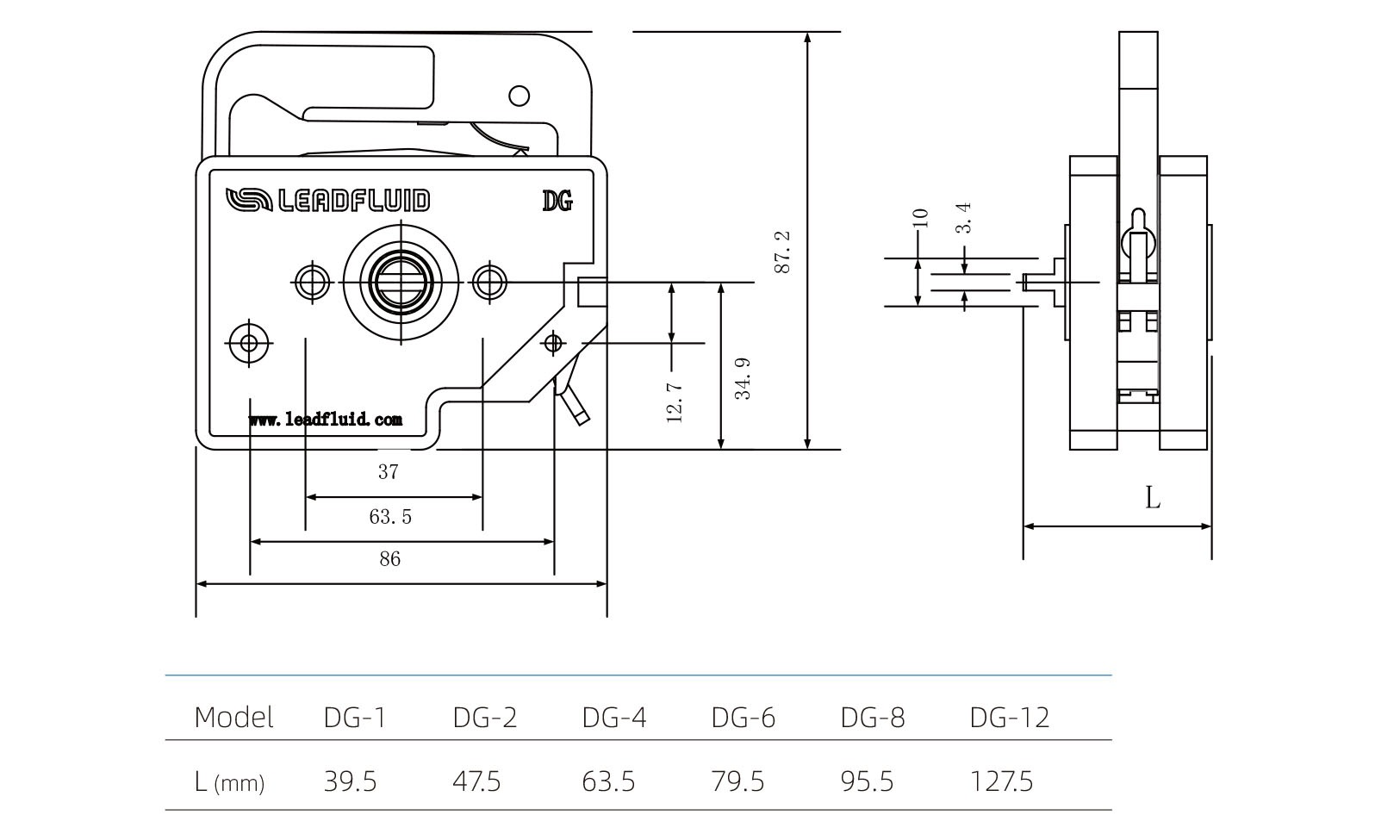

Dimension(mm)

Tube Life Comparison Table

Notes:

The above data are all test results obtained by Lead Fluid laboratory under normal temperature and pressure for the transmission of pure water, which are for reference only; the actual service life may be affected by specific factors such as pressure, temperature, medium characteristics, tube batch and wall thickness; for specific problems, please contact Lead Fluid engineers to get better technic al support.

Statement:The final explanation right of above information belongs to Lead Fluid.